The May meeting will be at 6:30 pm on the 15th at the University of Tennessee Space institute, room H111.

All things Spring\Summer are upon us. Lawn mowing, garden (flower and vegetable) tending, and vacationing all compete with shop time. All winter long I’ve longed for warm weather and more time for making some sawdust. But the only dust I made this past week was behind a tiller – sigh.

The summer also holds opportunity for wood club related diversions. The tool sale is eminent (May 19th) and the club picnic is not far behind. See more details regarding coming events in this newsletter.

May 15th – Loyd Ackerman – Using Sketchup for the Blue Monarch Project

A complete list of scheduled programs can be found on the website.

If you change phone number, email address, etc.; please notify Chuck Taylor, membership chairman (931-728-7086 or taylor_cw@charter.net. This will allow the membership listing on the web site to reflect the current and up-to-date information of all our club members.

I didn’t get any report about new members, but we did have a guest last month. Mrs. Alice Jensen attended the April meeting and also participated in the shop tour.

The Splinters Carvers meet at Jim Jolliffe’s shop on the first and third Saturday's of the month from 8:30 am to 10:30 am. The shop is located at 201 Jolliffe Acres Ln, Tullahoma. Tools and wood are available at the meetings, just bring yourself and try your hand at carving!

We strive to get the right picture associated with the right presenter, but oftentimes it's hard. So speak up when you give your name and we'll try hard to get everything matched up.

|

|

Doug Dunlap brought two walnut bowls. One bowl had cracked. The second was finished with lacquer. |

|

Doyle McConnell displayed a pepper mill made with four pieces of plywood and walnut. The glue in the plywood was green and made an interesting design on the mill. |

|

|

Rowland Bussler showed a group of bottle stoppers made from various scraps. He showed how he used snap jewelry to decorate the tops. |

|

|

Ross Roepke brought a violin shaped stool made of cherry and finished with Danish oil. He also had a cross for church made of plastic which he said was a fun project. |

|

Levon Jones had a folding child's rocker to use as a pattern. Finish Val spar sealer and painted white. |

.jpg) |

Bob Brown showed a slideshow of furniture he made including two walnut tables, two cherry desks, a white oak bookcase, and a communion table. |

|

Richard Gulley showed a CNC child's rocker made from a pattern from a previous show and tell. He also had a CNC sign “Sometimes My Train of Thought leaves the station without me”. |

|

Micky Knowles sdisplayed a bowl made from box elder finished with sanding sealer and lacquer. |

|

|

Bob Leonard brought wooden knives and sheaths he had made using sycamore. He explained he was trying to get a Damascus steel look on the blades. |

|

Felix Rees showed a small wheelbarrow he made for his grandson. It was made of red oak and finished with marine spar varnish. |

Saturday after the April meeting, a group of about 20 met at Hardee's at 8:30 a.m. and enjoyed a quick breakfast.

We then moved on to Tom Gillard’s residence to look over his new shop. Not as much room as his old downtown building, but a very comfortable and well-built structure in his own back yard. Who could ask for more?

We then followed Jack Kincella into Moore County and saw where Jack does his own special finishing magic. He gave an informative demonstration of a French polish technique that used paraffin oil instead of shellac. There’s a lot of talent in the club and Tom and Jack are two fine examples of same. Below is Tom's shop on the left, and Jack's shop on the right. There are more pictures of the tour on the website gallery.

http://www.songofthegreatlakes.com/index.htm - This woodworking website has lots of shop tips, general information, and a special section with step-by-step instructions on the construction of a five-string banjo.

https://www.joewoodworker.com/ - Free vacuum press plans, project links, and veneering information.

https://miterset.myshopify.com/pages/demo - If you make miter segments, you have to see this well-made jig. A bit pricey ($69.95), but it’s amazing.

Combination Squares - Text by Tom Hintz (newwoodworker.com)

Regardless of how hard we look to the emerging technologies in woodworking, we often find that the tried and true devices of yesterday remain the best choice. Such is the trusty combination square.

I keep two good quality combination squares in my shop. One has a 16-inch blade, the other 6 inches. Of the two, I use the 6-inch version more, but will part with neither.

Woodworkers often find themselves repeating the same measurement on several pieces of wood as we lay out a project. Opposing mortises must in identical locations on legs for the rails to be straight and square. Many other parts require the same accuracy on two or more pieces for the project to come out correctly.

Certainly, layouts can be accomplished with a tape or ruler. However, measuring once to set a combination square, then using that to place marks in exactly the same place on multiple work pieces is much faster, and more accurate.

I have also found that the small combination square is the best tool I have for checking the depth of a groove or dado. I can apply that same measurement to setting the depth of cut on the router. When I need to draw a line on a piece of wood, there are few times when the combination square will not work as good or better than anything else in the shop. This is particularly true when setting a reveal or marking a relatively small area along either the long or short axis of a piece of wood. Set the combination square and slide it along, guiding a sharp pencil and no matter how many pieces I have to do, they are all the same.

Woodworkers are understandably concerned with accuracy, and repeatability. That is why so many pay top dollar for the best machinery they can afford. Accuracy costs money, in most cases. However, combination squares are very affordable. To make the deal better, they can help eliminate mistakes that waste wood and time.

If you do not have a good combination square, get one. If you have one, use it. Your woodworking will be better because of it.

If you have items for sale or trade, let Loyd Ackerman know and he will post to the website list.

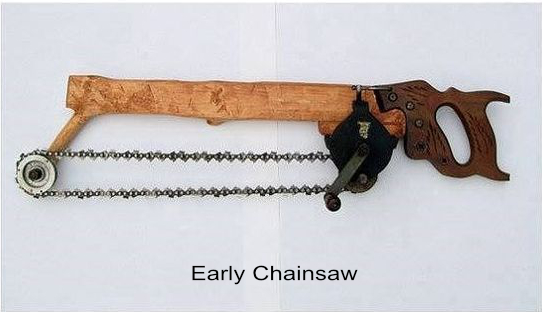

I’ve always been interested in tools and their development. I thought you might be intrigued by these early forerunners to our modern power tools:

That’s all for this month, see you on the 15th. Watch out for SPLINTERS.