|

|

Paul Credle - Tullahoma |

|

|

Ron Bailey - Winchester |

HAVE YOU PAID YOUR 2016 TVW DUES? The

membership chairman, after the April club meeting, removed the names

of people that did not pay their dues for the year 2015 and have

not, thus far, paid their 2016 dues. If you have forgotten to pay

your TVW club dues, please contact Chuck Taylor, membership

chairman, or Paul Jalbert, treasurer, to get your name back on the

membership listing.

It’s our Annual Spring Picnic!

Saturday, May 14, 2016

|

This all happens at beautiful Falls Mill…

(134 Falls Mill Rd.,

Checklist of things to bring:

·

Your favorite covered dish (the club will provide drinks,

plates, and utensils)

·

Something for the Auction (and your checkbook J)

·

Lawn chairs

TVWW friends and

families!

See you May 14

The Turning Bee is an event in which newer

wood turners are paired with a mentor for a hands-on experience to get

instruction and advice on how to turn a bowl. This event has spawned the

careers of many TVW members in the wood turning skill.

It is a great learning environment and even better fellowship with other

club members.

If you have not previously

registered to attend the event, you need to contact Larry Wendland

(contact information below) soon and get your name on the list. They

need to know soon, in order to prepare enough bowl blanks for everyone.

You are invited to attend this

year’s event at Larry Wendland’s shop for some turning tutorial and some

camaraderie with fellow woodworkers.

Date: June 25, 2016

Time: 8 AM until we’re done

Cost: $10 each

Location: 224 Dunk Blanton Road, Tullahoma TN, 37388

Contact: Ph. (931) 563-7445 culets@gmail.com

Unless you’ve already enrolled, please

contact Larry to confirm your plan to attend.

This “once in a lifetime” experience only

happens once a year.

|

|

Loyd Ackerman brought in pictures of a

plaque he made for the "Donor Tree" he made with his CNC

machine for the Lobby of the Manchester Arts Center. He also

brought

a

clock, featuring a negative relief picture made from Corian,

and cut on his CNC machine, which he had cut as the main accent

for the clock. The cutout was back lit with LED lights. |

|

|

Doyle McConnell showed us a trick which cleans the buildup off

of saw blades.

Soak the Sawblade in Ammonia for about 30 Minutes, then brush lightly with a brush. He then showed us the beautiful pepper mills made from oak and cedar, the wood coming from the old family home which had been in the family for generations. |

|

Doug Dunlap drought in a

segmented vase, made from 180 pieces of oak and cherry

woods. He claimed to have messed it up, and corrected it by

making another one, this time using 193 pieces to get his

proportions correct. |

|

|

Bob Stancil showed us several wooden

bowls he had turned from Magnolia wood. Several were around

12 inches,

deep sided, which he had to made a special tool rest for. He also brought a

cherry bowl carved from the burrel, finished with Danish

oil,and a

bowl turned from the crotch of a hickory tree. It was bell

shaped, and about 10 inches. |

|

|

Ross Roepke brought in a rocking horse he had made about 28 years ago for his first grandchild. He saw the plans in a wood working magazine years earlier, and has now made 3 for his children, and several for the grandkids. |

|

|

Jim Everett brought in pictures of the intarsia piece he is working on entitled "Riding with Private Ryan", based from a song by the same title. He is also working on a new piece for the Wounded Warrior project and Homeward Bound, severL charities helping the PTSD vetterans, for which Charlie Daniels is helping him to get signed by other Musicians. |

|

Bob Addington

brought in a

rocking chair he cut from MDF on his CNC machine for his

grandchildren, that come apart, and when assembled, are held

together by one plug. |

|

John Hartin

brought three

bowls one a tulip shaped bowl he turned from scrap spalted

hackberry, and a natural edged tulip shade bowl, both turned

with the golden ratio in mind while making them. He also gave a

short demonstration on how not following the golden ratio can

give a perfect piece a sense of not looking right. |

|

|

Judy Bennett

brought in her intarsia niece featuring a

qualia bear, which she will be sending to NC as a baby gift.

It's features woods from spalted Cherry, maple, walnut, and

finished with a semi gloss finish. |

|

Felix Rees brought

in a

turned lamp, with a 10 inch base, made from red oak and

walnut, sealed with a polyurethane sealer. |

|

|

Noel Johnson showed us a Scandinavian natural edge bowl, which is called a Royal Paulownia Bowl, very light weight, made from cherry wood. He sealed the edge with CA glue to stabilize it while turning, and kept blowing air through it from behind to help to dry it as he was turning it. |

|

|

Paul Jalbert showed us the sharpening jig he made to help him to keep his carving tools always at the peak performance. He also brought the plans, and gave a brief demo on how to make it. It was made from cherry and covered in polyurethane. |

|

Mickey Knowles brought in a 12 inch bowl he turned from a spalted maple. It had a bad portion in the wood, which he fixed with coffee grounds, sawdust, and CA glue. He used a cellulose sealer, and finished it with a food grade wax. |

|

Greg Myers showed us the Christmas ornaments he had turned on the lathe, and a cherry bowl. He had finished them with a high speed turning polish. |

|

|

Jim Van Cleave

brought in

several serving trays he made for his wife several years

ago. They were made from walnut wood, and one of them had

handles on it. He made them using a router and a cardboard

cutout pattern. He suggests starting off with good grained

walnut, and about 10 lbs. of sandpaper. He also made a small

matching table to go with the trays. |

|

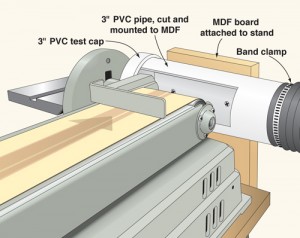

Conquering the final frontier of dust

collection My stationary belt sander was one of the few tools I had without a dust-collection port. This was a big-time problem because fine sanding dust remains suspended in the air for a long time. To tackle this challenge, I devised a dust-collection hood out of 3″ PVC pipe. I began by cutting a collection slot into the 3″ pipe and glued a PVC test cap on the end. I then mounted the pipe to a slab of medium-density fiberboard (MDF) attached to the belt sander stand at the outfeed end of the belt. After a few wraps of duct tape around the free end of the PVC to increase its diameter, a 4″ dust-collection hose slips over the pipe and is held in place with a band clamp. —Roy Davis, Phoenix Courtesy of Wood Magazine |

Always wear your

safety glasses in the shop