Next Meeting February 16

The meeting will be at 6:30 pm at the University

of Tennessee Space institute, room H111.

February 16, 2016 - Paul Walters

from Klingapor Sandpaper company will discuss Abrasives/Sand Paper and

how to use them on projects. We arranged for this one because some of

our members use their products and had questions and some problems.

Company rep programs are always good fun.

-

Want to know who your

TVW officers are? Click

here

-

Be sure to check out all the "up coming events" the executive

committee has scheduled for the current year. Click

here to view the

"Event Schedule".

-

REMINDER

- Please remember to wear your

name tag at our meetings so that our new members will know who you

are.

-

Volunteer Mentors for Club Members.

Click

here (bottom of page)

MEMBERSHIP INFORMATION

New Members joined at January meeting

|

Douglas Brown - Winchester, TN |

|

John Hill

- Shelbyville, TN |

Membership Information

Dues: If you have not paid your dues

for 2016, please do so at the next meeting.

If you change phone number, email address, etc; please notify Chuck

Taylor, membership chairman (931-728-7086 or taylor_cw@charter.net. This

will allow the membership listing on the web site to reflect the current

and up-to-date information of all our club members.

Two Great Website about all types of wood

The Wood

Database

Woodpics

CLUB LIBRARY NEWS

If you have media you would like to

donate, or would like to reserve a certain video, contact August Dobert.

His contact information is listed on the membership roster in the "Club

Info" section.

CARVER'S CORNER

The carvers are meeting twice a month on the

first and third Saturdays from 8:30 to 10:30 am at Jim Jolliffe's shop.

CHEROKEE WINDS FLUTE CIRCLE NEWS

Everyone is invited to come and participate or just

come to listen.

Contact Ron Reimers @ 931-308-5196 or

ronreimers@hotmail.com for additional information.

Notes

Kenneth (Dale) Daniel will sharpen TVW member blades. His location is 2007 Ovoca Road,

Tullahoma.

Phone –

931-455-5024, cell – 931-247-4753.

Tullahoma Builders Supply

is now a great resource for the full line of the duralac lacquer

products at very competitive pricing. folks can see Randy and let him

know they are from the wood workers club for extra help. also many

innovations are out for re-finishing and repairing furniture. they

include new stains, finishes and spot repair items and processes. if

there are any needs or questions, I would encourage folks to contact me

at

jackkincellafurnitureman@outlook.com

NAME TAG INFORMATION

If you are a recent new member or had requested

a new name tag, a box of name tags will be available at the next

meeting. In the

future, name tags will be made for new members and available for pickup

at the next regular monthly meeting. Name tags for other

members will be made upon request only and will also be available for

pickup at the next meeting. Please contact Chuck Taylor (931-728-7086 or email

taylor_cw@charter.net) for information or name tags.

January

Show & Tell

|

Johnnie Brown brought in a

beautiful

fire truck he started in 2005, and after taking a long

break, finished it in 2015. It is constructed from

walnut

and maple. All totaled, he estimated it took him around 100

hours to build. |

|

John Hill

brought in some

coasters

and holders made from cherry and walnut woods,

bracelets

also made from cherry and walnut, and pictures of some furniture

made from hickory. |

|

Ross Roepke brought in some

examples of an easy to make

holder

to keep your work of the bench while it is being stained. It was

made from pine. |

|

Vince Zaccardi

brought in

several

bowls he had turned on the lathe, some as an experiment. One

was from an unknown wood; one was turned from heaven wood. It

was finished with a wax. |

|

Geoff Roehm

brought in a

handmade

guitar he handcrafted from several different woods, some

were spruce and mahogany and finished with a UV polyester. |

|

Richard Gulley

brought in a "climbing

monkey" toy that climbs up a rope he had made from oak, and

a picture

craved out of Corian material on his CNC machine. He also

hand made the frame in which it was held, made from oak finished

with 3 coats of polyester mixed with mineral spirits. It was

back lit from a coil of LED lights. |

|

Denis Urbanczik,

a new member, brought in a

bench

made from white oak, featuring false

mortise and tenon joints, and finished with dark walnut

stain and Sherman Williams wood finish. |

|

Gregory Myers

brought in a

"dizzy"

bowl, whisk was first cut on the band saw, re-glued, and

then turned on the lathe. |

|

Jim Everett

showed pictures of

double

doors he made featuring a horse, put together in intarsia

style. He designed it so when the doors were closed, the

horse’s

muzzles would overlap. |

LINKS OF INTEREST

To view the "Links of Interest" on our web site, please click

here.

Click

here to see the Exchange Opportunities

If you have additional woodworking items for sale or are looking for woodworking

items, please send information to Chuck Taylor at 931-728-7086 or email

to taylor_cw@charter.net .

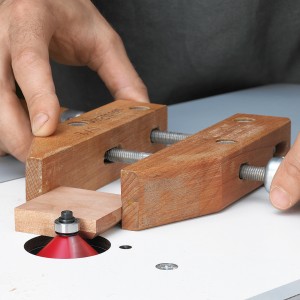

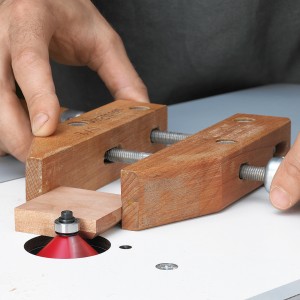

Shop Tip

|

Small-part routing safety

A wooden handscrew clamp serves as

a safe “extension” of your hands, gripping the small part firmly

while sitting flat on the table surface as you rout its edges.

http://tips.woodmagazine.com/

|

Square foot gardening

Your editor is building some square foot Gardening

boxes.

There is some woodworking involved

Additional information available at:

www.melbartholomew.com

Square foot

gardening is the practice of dividing the growing area into small square

sections (typically 12" on a side, hence the name). The aim is to assist

the planning and creating of small but intensively planted vegetable

gardens. It results in a simple and orderly gardening system; from which

it draws much of its appeal.

The Box –

build a frame from any non-treated, 6-inch-wide lumber – or other

similar material. When you place the box on the ground be sure to first

put down weed mat or landscape fabric to prevent weeds from growing into

your garden.

Best Size –

4×4 box, but be creative. As long as you don’t make your frame wider

than 4 feet, you can design your own look.

Fill boxes as listed

below, do not use any soil.

1/3 Coarse Grade

Vermiculite

1/3 Peat Moss

1/3 Blended Compost

Work safely and don’t take unnecessary chances

with your woodworking tools

Want a good tip concerning your current project?

TVW SUPPORTERS

The following companies are supporters of the TVW club. Click on

their "logo" to go to their web site.