Next Meeting September 15

The meeting will be at 6:30 pm at the University

of Tennessee Space institute, room H111.

|

September 15 -- Doyle McConnell

will do a program on Turning Christmas Decorations. |

-

Want to know who your

TVW officers are? Click

here

-

Be sure to check out all the "up coming events" the executive

committee has scheduled for the current year. Click

here to view the

"Event Schedule".

-

REMINDER

- Please remember to wear your

name tag at our meetings so that our new members will know who you

are.

-

Volunteer Mentors for Club Members.

Click

here (bottom of page)

NEXT MAJOR TVW ACTIVITY:

Coffee County Fair

September 19 to 26 -- Details will be announce

at the September meeting by Doyle McConnell

MEMBERSHIP INFORMATION UPDATE

If you change phone number, email address, etc; please notify Chuck

Taylor, membership chairman (931-728-7086 or taylor_cw@charter.net. This

will allow the membership listing on the web site to reflect the current

and up-to-date information of all our club members.

TVW NEWS AND NOTES

Two great Website about all types of wood

The Wood

Database

Woodpics

CLUB LIBRARY NEWS

If you have media you would like to

donate, or would like to reserve a certain video, contact August Dobert.

His contact information is listed on the membership roster in the "Club

Info" section.

CARVER'S CORNER

|

The Carvers met on Saturday, September

5 at Jim Jolliffe's shop, which has become a popular

place. There were twelve carvers present including Jim,

his father-in-law Tom and his neighbor Greg, Dick,

Allan, Sharon, Kelton,

Ken B and Ken G. Steve, Blue and Paul. The increasing

number of carvers at each meeting and the wide variety

of carving interests within the group is a testimonial

to the value of the Club.

|

|

|

New carvers and visitors are always welcome.

The carvers are very grateful to Jim for hosting the meetings. The

carvers are meeting twice a month on the first and third

Saturdays on the month from 8:30 to 10:30. The attached photo is a group

shot of the Carvers as they plan future events. Some of the events that

we have planned in the near future are:

1) Participation in the Cowan Festival on the weekend of September 18,

19 and 20 to show, sell or demonstrate wood carving skills. Tent set-up

is Friday at 1:00 pm, occupy the tent on Saturday from 9:00 am to 9:00

pm andon Sunday from 11:00 am to 5:00 pm and tear down afterwards.

2) Meet at Phil Bishop's shop on Saturday, October 3 at 9:00 am to clear

out the rest of the wood we have stored there.

3) Make arrangements to use the Carvers fund to buy a carousel horse

rough-out from Horsing Around as the next Carvers project.

CHEROKEE WINDS FLUTE CIRCLE NEWS

Everyone is invited to come and participate or just

come to listen.

Contact Ron Reimers @ 931-308-5196 or

ronreimers@hotmail.com for additional information.

Note

Kenneth (Dale) Daniel is back in business and will

again sharpen TVW member blades. His location is 2007 Ovoca Road,

Tullahoma.

Phone –

931-455-5024, cell – 931-247-4753.

NAME TAG INFORMATION

If you are a recent new member or had requested

a new name tag, a box of name tags will be available at the next

meeting. In the

future, name tags will be made for new members and available for pickup

at the next regular monthly meeting. Name tags for other

members will be made upon request only and will also be available for

pickup at the next meeting. Please contact Chuck Taylor (931-728-7086 or email

taylor_cw@charter.net) for information or name tags.

August

Show & Tell

|

Jack Kincella - He made repairs to a

1800's

walnut bed (with 11 pieces, shown by pictures) and Paul

Jalbert did the carving, with Ken Gould making the metal hooks.

Tom Gillard also helped. A lacquer finish was applied.

|

|

Tom Cowan - He

made a

chest out of white oak, pine for the top and black turned

wood accents and knobs, and

carved panels on the sides. He used stain on green and red

trim, with a lacquer finish. |

|

Paul Jalbert - He made a

carving

of a wedding date on a cherry board (O'Brian) with a Watco

spray-on finish. |

|

Richard Gulley - He carved a running

deer on a board and a picture of three people on Corian,

using a CNC machine. |

|

Doyle McConnell - He turned a

peppermill out of maple and used a lacquer finish on it. |

|

Doug Dunlap- He

turned

two segmented bowls out of cedar and cherry and finished

them with 3 coats of lacquer. |

|

Bob Addington - He made

four CNC

carvings of cows, birds and horses on oak and cherry boards.

His finish was early chestnut stain. |

|

Jim Acord - He turned a

mallet

out of white oak and pear and used a wipe-on polyurethane finish

on it. |

|

Gary Runyon - He

made a

shoulder plane out of Texas ebony wood with a thick steel

chisel blade. He used a special saw to cut the slot, and

finished it with Min-Wax and oil. |

|

Eric Strotheide - He made

two toy

wood cars out of walnut and ambrosia oak, and used a Danish

oil and Min-Wax finish. |

|

Ross Roepke - He made a

small

table out of mahogany and eucalyptus with

carvings

on top, a lacewood veneer, and a drawer. He used deft oil

finish on it. |

|

Jim Everett - He made an

intarsia

wood panel showing a squirrel and cat in a window looking

out at it. He used water-based polyurethane and Krylon finish on

it. |

|

Bob Stancil - He

turned a

20" chestnut bowl with a black inlay in the bottom. He used

a butcher block oil finish on it. |

|

Mickey Knowles - He made a cherry handled ice

cream

scoop and a wood mount for a deer antler and slate knife.

|

LINKS OF INTEREST

To view the "Links of Interest" on our web site, please click

here.

Click

here to see the Exchange Opportunities

If you have additional woodworking items for sale or are looking for woodworking

items, please send information to Chuck Taylor at 931-728-7086 or email

to taylor_cw@charter.net .

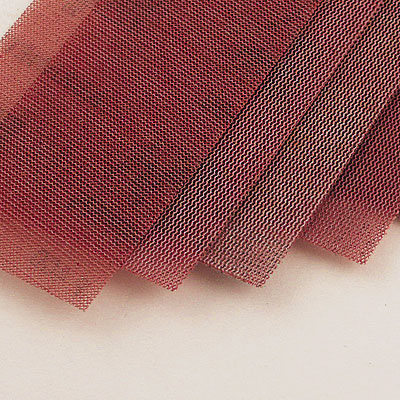

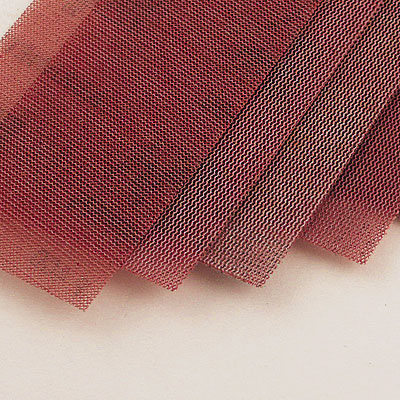

Shop Tip

Abranet Mesh vs Sandpaper

Abranet is a mesh abrasive with thousands of

small holes. The distance from each abrasive grit to the nearest dust

collection point is only half a millimeter. This provides efficient dust

extraction from the entire surface of the material.

- Due to the fantastic extraction ability, You can use it wet or dry.

Cuts much faster than paper, outlasts any other type, and when it loads

up, you simply smack it against the lather, or anything else, and it

clears the openings and is ready to continue.

- Abranet has a much longer lifetime and retains its original sanding

performance much longer than traditional abrasives. This means that

sanding can be carried out more quickly and more effectively.

- The finish is smooth and scratch-free when compared to standard

sandpaper

- Abranet sheets and discs outlast traditional abrasives for greater

efficiency.

- Immediate dust removal allows for better sanding

- Even grain distribution provides more consistent finish and improved

surface appearance.

- Extended product life requires less use of materials.

- Better work environment and less environmental impact.

Work safely and don’t take unnecessary chances

with your woodworking tools

Want a good tip concerning your current project?

TVW SUPPORTERS

The following companies are supporters of the TVW club. Click on

their "logo" to go to their web site.