The January meeting will be at 7:00 pm on the 21st at the University of Tennessee Space institute, room H111.

The January program will be presented by Jason Lawrence. Jason will discuss and demonstrate carving techniques he uses in creating scale models of various items.

See you at our January meeting on the 21st .

|

|

Jesse Potter - Manchester |

|

|

Jesse Luke Potter - Manchester |

|

|

Don Sellers - Manchester |

|

|

Dakota Slatton - Cowan (actually joined in October) |

(Joining at the December meeting)

Be sure to meet all of our new members and welcome them to the club.

We recently lost two long-time TVW members.

Tom Church was a club member since 1985,

being one of the original founders of the club.

Howard Coulson also joined the club in 1985, one month after Tom joined. He was a TVW member until 2010.

Don’t forget the Exhibition, “In the Spirit of Fine Woodworking”

, is the first week of March

2014. The committee is already working hard to make this event a huge

success.

For a successful Exhibition, we need you to participate by entering

display items for the Exhibition.

The Exhibition dates are:

Sunday March 2 will be Opening Day and Reception – open 2 PM until 5 PM.

Monday March 3 through Saturday March 8 will be open from 11 AM until 7

PM.

Sunday March 9 will be closing day – open 2 PM until 5 PM

Please get your entries turned in to Bob Addington early. The forms for

entry are available on the website and will be available at the next

monthly meeting. Fill them in as soon as you can so that we can get an

idea of the number and scope of exhibits for planning purposes. Entries

will be accepted until mid-February but early entries help a lot.

Stay tuned to Splinters and the TVW website for latest developments.

The annual TVW Christmas party was held on December

13th. If you did not attend, you missed a really great party.

Thanks to Karen Browning, chairperson, and her team for doing a

wonderful job coordinating the dinner and decorating for the event. The

food was great, the decorations were beautiful, all the gifts were

wonderful and the fellowship was really special.

The singing of Christmas songs, led by Richard Gulley was really great,

as always.

A good time was had by all attendees.

The “Grand Door Prize”, a $250 gift certificate from Woodcraft, was won

by Joe Ferraro

.

.

Congratulations to Joe, who picked up his prize at the December meeting.

The Carvers Clinic did not convene in January. They plan on meeting on February 1st.

The carvers normally meet on the first Saturday of each month at Phil Bishop’s shop. Anyone interested in carving is welcome to attend these monthly meetings.

The carvers normally meet on the first Saturday of each month at Phil

Bishop’s shop. Anyone interested in carving is welcome to attend these

monthly meetings.

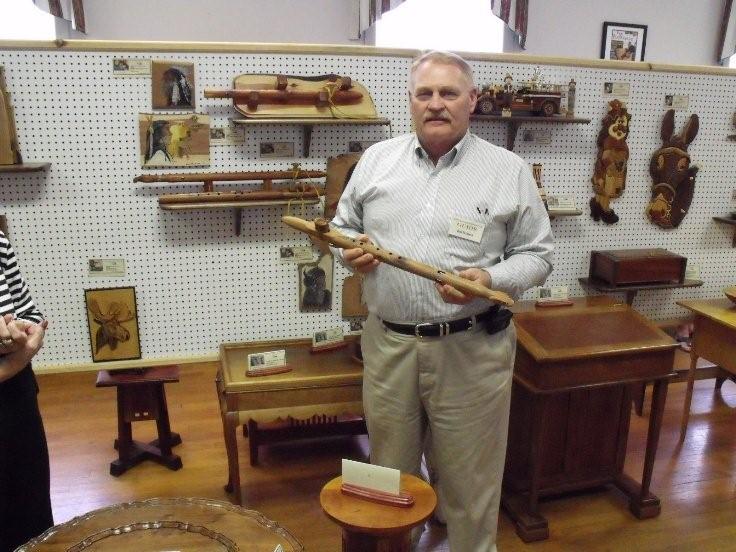

The flute circle group met on January 18 at the Cowan

artisan's shop. The flute circle group will not meet during the month of

February.

The next meeting will be in March and will be announced at the February

TVW meeting.

This group is for anyone interested in learning how to play the native

flute. Even if you don’t have one, please come and we will take care of

you.

Contact Ron Reimers @ 931-308-5196 or ronreimers@hotmail.com for

additional information.

Come and join the fun and fellowship with the “Fluters”.

What a year for the forum in 2013. There was lots of questions ask

and many, many answers provided. Looking forward to a great year in

2014.

The forum is the place to “check out” and is booming with “expert”

solutions to your woodworking problems and great advice.

You would absolutely be amazed at the wealth of knowledge that your

fellow members have to offer at a great price!

Start the new year off in great fashion. Check out a

DVD from the library and hone your skills in a special area. If you did

not try it in 2013, don’t make the same mistake this year. You are

missing a great opportunity to learn new techniques and brush up on old

ones.

For a complete list, see Henry Davis at club meetings, email him at

hdavis37@charter.net or call him at 393-3191 and leave a message.

Giant

Show & Tell at the December Meeting

Giant

Show & Tell at the December Meeting

|

Tom Gillard – described a table he is building for a customer, and discussed the difficulty of achieving straight enough edges to glue-up the table’s is eleven feet long, fifty inches wide, and one and one half inches thick poplar three-board top. After several unsuccessful attempts to prepare the boards using power tools, he finally accomplished the task using hand planes. He credited his success to lessons learned from TVW club members. |

|

|

John Duval – brought pictures to show how he transported and cut bowl blanks from four split sections of a freshly felled thirty-one inch diameter cottonwood tree. Each 320 pound section was large enough to provide a twenty-four-inch-diameter (48 pound) rough bowl blank and enough shavings to fill four 55-gallon trash bags. Stay tuned to see the finished bowls. |

|

Henry Davis – brought pictures to show his method for cutting a straight edge on a rough-sawn board. He showed the guide he made for his thickness planer to keep 3/4” by 1 1/2” boards square while removing saw marks from the narrow edges. He showed the adjustable girth weaving frames that he builds and showed examples of the handmade girths woven by a customer. |

|

Matt Brothers – brought before and after pictures of an antique chopping block that he flattened for a customer. He used a plunge router and cradle on a guide frame to provide a level cutting reference. Matt also brought photos of one of a three-drawer walnut side chest (one of two) that he built to match a bedroom suite that he has been working on. He also showed a cherry bookcase that he built using seventeen-inch-wide boards for the top and sides that he got at New Market. |

|

Doug Dunlap – brought a segmented bowl and pepper grinder that he made after attending one of Loyd Ackerman’s seminars. Both pieces were turned from 12-segment rings of alternating walnut and oak blocks. |

|

|

Don Sellers– brought a large kaleidoscope and stand made from mahogany with contrasting ash inlays. It is one of five that he built for Christmas. |

|

Josef

Maienbacker – brought a

lavishly carved tray that he

bought at a yard sale for three dollars. |

|

|

August Dobert

– brought three goblets that he turned twenty-five

years ago. One had a large wooden arrow sticking through

holes in the bowl. |

|

Gary Runyan – brought four Christmas tree ornaments made by Howard Gilliam from sassafras, cedar, and redheart. |

|

Ken Gould – brought pictures of a carved bear (1986), a frog (1993), a turned pencil holder (1999), a recently turned gavel, and a five-foot-tall functional nutcracker that he built from walnut, cherry, and maple. He also showed photos of two gavel plaques that he made for presentation to outgoing

blacksmith association officers.. |

|

|

Jim Van Cleave – brought a carved pair of hands that he bought at a yard sale for fifty cents. |

|

|

Loyd Ackerman – brought a pair of personalized trivets and a jewelry box, all with decorative designs carved by his CNC router. He suggested that for such mitered-corner boxes, cutting the miters at 45.2 rather than 45.0 degrees will give the tightest-fitting corners and not require splines |

|

|

Ross Roepke – brought a scroll sawn sleigh made by Don Helton that he bought for thirty-five dollars. He also brought a Queen Ann style leg bandsawn from a Fine Woodworking pattern. He described how critical it is to start with a well designed pattern and to follow the contours very closely, as any minor variation will show in the final product. He uses a scraper made from an old saw blade to do the final surface smoothing. Ross recently burned out the motor on his planer and inquired about a place to get it rewound. Reid Electric in Shelbyville was recommended. |

|

Fred Heltsley – brought a “swizzle stick” that he whittled on the way to the 1960 Boy Scout Jamboree in Colorado Springs (one of his first wood carvings) and a walnut boot jack that he made for his father in the 1970s. |

|

Bob Leonard – brought a farm scene with over twenty-five implements and figures that he carved. He also brought along his more recently carved “prize winning” Smiley caricature. |

|

John Harton – brought three of eight vessels that he recently turned from a large walnut tree. Unknown circumstances in the past had produced two adjacent trunks that had grown tightly against each other, resulting in a sapwood-free and bark-free interface. John exploited the crotch-like interface to produce a unique natural-edged bowl with no visible sapwood or bark, but rather a burl-like edge texture. Because one trunk had been dominant, the interface bulged toward the more-deformed inferior trunk, causing a concave surface on the blank John selected and resulting in the very unusual edge contour. |

|

|

Jim Everett– brought a cabinet door that he recently made with an intarsia rendering of Blarney Castle on the inset panel. He is currently working on a similar door featuring Edinburgh Castle and another with a tenor sax made from osage orange and basswood. These and many other creations will be featured at the Celtic Cup in Tullahoma. |

|

Ken Burgess – brought five cottage Christmas tree ornaments that he made from cottonwood bark. He explained how the backs (tree side)of two pieces of bark were flattened and glued together. Once the outside carving is finished, the pieces are split apart, hollowed out, and re-glued to make a

lightweight ornament. |

|

Chuck Taylor – brought two bowl blanks that he turned from fresh-cut apple wood. In spite of being properly stored to dry in paper bags, they warped severely. Chuck says this is not the way it is supposed to work. Stay tuned to see if he can salvage one or maybe both of the bowls. |

|

Mickey Knowles – brought a bowl turned from Chinese tallow tree wood. The non-native plant has spread and is now common in south Alabama where it is considered a “weed” tree. |

|

|

Doyle McConnell – brought a seam ripper with a walnut handle turned by Bob Reese who could not be present because of recent health issues. Doyle also brought two maple pepper grinder “works-in-progress” that his shop elves plan to complete in time for Christmas. |

|

|

Richard Gulley– brought a Christmas wreath with ribbon bow that he carved from poplar and cherry using his CNC router. Richard’s least favorite woodworking tasks are sanding, finishing, and cleanup. Now that he has the CNC machine, it does all the fun stuff and leaves those very tasks to him. |

|

|

Sharon Wright – brought a toilet paper roll cover that Newton designed to foil their cat’s game of shredding the tissue and scattering it throughout the house. |

|

Vince Zaccardi – described William Ng’s 5-cut method of precisely aligning a shop-built table saw sled. See a materials list for the sled and a descriptive video of the alignment procedure on Ng’s website at: http://wnwoodworkingschool.com/5-cuts-to-a-perfect-cross-cut-sled/ |

Be sure to be on the lookout for the 2014 calendar of events. The executive committee will be meeting and setting the events and dates in the near future. The event calendar will be posted on the web site as soon as the year's activities are set.

To view the "Links of Interest" on our web site, please click here.

Click here to see the compiled list of items that are for sale by club members

If you have additional woodworking items for sale or are looking for woodworking items, please send information to Chuck Taylor at 931-728-7086 or email to taylorcw@bellsouth.net .

TABLE-SAW SAFETY ----- Align your table-saw splitter for safe rip cuts

Your saw’s splitter and anti-kickback pawls are two important

components of accurate and safe rip cuts. As its name implies, the

splitter keeps the kerf open after the blade makes the cut,

preventing pinching that can burn a cut. Follow this simple

procedure to check that the splitter is centered behind the blade.

Loosen the mounting bolts to shift the splitter behind the blade.

The spring-loaded anti-kickback pawls are the pointed guards held

against the stock with pressure. The pawls glide over the stock as

long as the cut is proceeding normally, but jam into the wood if the

blade tries to shoot it backward toward you during a kickback.

Prevent an accident by making certain that the pawls operate

correctly.

Use a straight piece of wood to check that the splitter is directly

behind the blade so it doesn’t interfere with the cut.

------ Compliments of Wood Magazine "Daily Shop Tips" Website --------

Visit this web site for “tips for every situation”: http://www.woodworkingtips.com/etips/

The following companies are supporters of the TVW club. Click on their "logo" to go to their web site.