The February meeting will be at 7:00 pm on the 19th at the University of Tennessee Space institute, room H111.

The February program will be presented by one of our members, Loyd Ackerman. The program title is “Turning with Staves -- Using Staves (straight or tilted) in Segmented Woodturning”. Come out and see how Loyd designs and creates his segmented turnings with the use of staves in his designs.

See you at our February meeting on the 19th.

(Becoming a member at the January meeting)

Jim Poteet …………… Monteagle

Be sure to meet all of our new members and welcome them to the club.

The TVW Executive Committee will be meeting on

February 12th to discuss and set the calendar of events that will occur

throughout the year.

Additional information will be available at the regular meeting. If you

have suggestions for a seminar, workshop or program, please give your

request to one of the executive committee members.

We are all looking forward to another great year of activities. Please

give the new officers your support when they ask you to help.

Plans for the 2013 Tennessee Valley Woodworkers

Exposition are being finalized. Thanks to Dan Maher for chairing this

event.

There will be additional information presented at this month’s meeting

concerning the event.

The carvers normally meet on the first Saturday of each month and work on individual or group projects. Everyone is welcome to “join in”.

The next flute circle meeting is scheduled for

February 26th at 1 PM. The meeting location is Tom Cowan’s Artisan

Studio in Cowan.

The group meets on the last Tuesday of each month. Come and join the fun

and fellowship with the “Fluters”.is scheduled for

January 29th at 1 PM. The meeting location is Tom Cowan’s Artisan

Studio in Cowan.

Come and join the fun and fellowship with the “Fluters”.

As you know, the forum was recently lost, due to a “drive crash”. The forum is now back up and active. Take advantage of all the vast amount of knowledge you can get from the forum members. Thanks to those who worked hard getting the forum back up.

Why don't you make a point to try our digital library this year. You will be amazed at all the wealth of knowledge that can be found here. If you do not try it, you are missing a great opportunity to learn new techniques and brush up on old ones. Henry has the library “open” at each regular meeting. You can click here to view the library listings.

Please remember that you can now view some of the club DVDs on line. Go

to the library listing on our club website and click on the

underlined titles.

For a complete list of all items in the Digital Library, see Henry Davis

at club meetings, email him at hdavis37@charter.net or call him at

393-3191 and leave a message.

The 2013 TVW club membership dues are now due. If you are one of the

members who have not already paid

your dues for 2013, please pay the treasurer, Bob Addington at the

meeting or you can mail your check to Bob at his home address (249 Big

Oak Drive, Manchester, TN 37355).

Our dues are $10.00 for a single membership, and $15.00 for a family

membership (what a bargain).

January

Meeting

January

Meeting

|

Greg Myers - showed a shadow-box for display of medals and a matching flag case. He made both from tiger stripe maple and applied his own mixture of water-base aniline dye, and finish coats of shellac and lacquer. |

|

Jim Acord - brought a sample of walnut that he bought twenty years ago for $2 per log. What he discovered when he sawed into the wood was lots of hidden checks and cracks. He also brought a nice pair of mills for salt and pepper that he turned after attending Doyle McConnell’s Pepper Mill Workshop. |

|

Bob Addington - brought a candle holder, a pair of round boxes, and a heart and ribbon that he carved with his CNC router. He described problems with the boxes going out of round. |

|

Bob Reese - brought one of four wooden cars that he built for family member Christmas gifts using plans published in an old Woodsmith magazine. He found the plan dimensions inconsistent with each other and the instructions incomplete. The project required a surprising amount of work even though he used ready-made spoke wooden wheels ordered from Rockler. |

|

|

Dick Wollam - showed a stylized fox that he carved. The carving finish consisted of two coats each of lacquer and water-based urethane. |

|

|

Richard Gulley - showed a very unusual relief carved translucent Lithophane “portrait” that he made from a scrap of Corian countertop material. A planer was used first to thin the material to 1/4-inch. He then converted a scanned black and white photo print into a three dimensional surface contour and tool path file for his CNC router using PhotoVCarve software. Thin areas where more material is cut away pass more light and thus correspond to lighter regions in the photo. A 1/8-inch ball mill was used for the initial roughing pass, followed by a finish cut using a 1/16-inch ball mill. Richard also brought an Auburn plaque he made from hard maple using the CNC machine. |

|

Ken Gould - brought a wooden copy of an adjustable trammel used in the 18th century for suspending grease lights or cooking pots. Like the original, Ken’s copy has ratchet teeth for adjusting height and rings on each end for hanging. He pointed out that properties of wood make it a poor substitute for the stronger iron used to form the original rings. He brought a wrought iron bottle opener that he also made and described how its end ring was formed. A slit was first cut into the flattened bar with a chisel, the slit was opened with a round drift punch, and finally the ring was rounded and hammered smooth on the anvil horn. |

The link will be here.

To view the "Link of Interest" on our web site, please click here.

Click here to see the compiled list of items that are for sale by club members.

If you have additional woodworking items for sale or are looking for woodworking items, please send information to Chuck Taylor at 931-728-7086 or email to taylorcw@bellsouth.net .

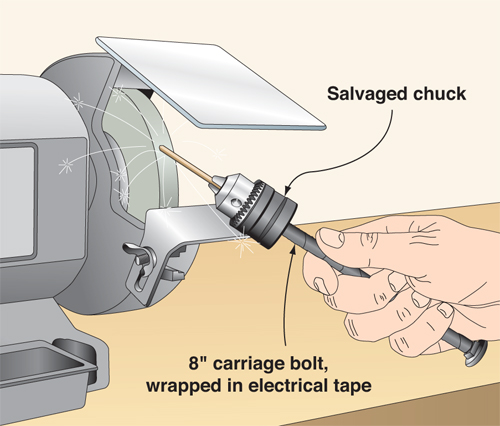

Holding small parts to a grinding wheel creates an unsafe shop

practice. The force of the wheel can yank the part right out of your

hand. And those pieces get hot! Pliers help but can muck up the threads

on bolts and threaded rod.

Here is a great solution to solve the problem. A 1/2" chuck from a dead

drill offers the perfect part-holding solution.

Thread the old chuck onto an 8" carriage bolt, then wrapped the bolt

with electrical tape to make it more comfortable to hold. To prevent

damage to threaded parts to be ground, I wrap the bottom section of

threads with electrical tape, and then tighten the part in the chuck.

The chuck holder works well for sharpening standard drill bits or for

sanding

dowels. This solution can be used on any small round objects that

require grinding.

------ Compliments of Wood Magazine "Daily Shop Tips" Website --------

Visit this web site for “tips for every situation”: http://www.woodworkingtips.com/etips/

The following companies are supporters of the TVW club. Click on their "logo" to go to their web site.