The June meeting will be at 7:00 pm on the 19th at the University of Tennessee Space institute, room H111.

The July program will be presented by Chris Lang. His

program will be “Early Cabinet Making in Southern Middle Tennessee and

Northern Alabama”.

Come to the July 17th meeting and hear what Chris has to

share.

Sept. 17-22: Coffee County Fair, Chairperson – Doyle McConnell, Location – Manchester, TN Time - TBD

Sept. 21 - 23: Polly Crocket Festival, Chairperson – Harry May, Location – Cowan, TN

Get all the information at the next TVW club meeting.

(joining at the Turning Bee)

Mark Ledbetter --------------- Cowan

Be sure to meet all of our new members and welcome them to the club.

.jpg)

The annual Turning Bee was held on June 30 at Tom Cowan’s shop. About 15 eager “turners” made lots of chips and received some expert instructions. This is always one of most popular events of the year and about 28 people attended the activity. Thanks to Henry Davis for being the chairperson for the activity. Thanks also go to those members serving as “mentors” and to Richard Gulley for preparing and serving the great lunch. As always, we express appreciation to Tom Cowan for hosting the day’s activities. Everyone went away with at least one rough turned bowl.

The carvers met on July 7 at the shop of Phil Bishop.

They worked on individual items and some worked on the new “Totem Pole”

project. Plans were also discussed concerning future activities.

The carvers normally meet on the first Saturday of each month and work

on individual or group projects. Everyone is welcome to “join in”.

The Flute Circle group met on June 26 at Tom Cowan’s

Artisan Studio in Cowan. Everyone was encouraged to bring a song that

they have been practicing during the past month.

The July Flute Circle meeting will be July 31 at 1 pm @ the Artisan's

Shop, 114 Main St. Cowan.

The group meets at 1:00 PM on the fourth Tuesday of each month at Tom

Cowan’s Artisan Studio in Cowan. Everyone is welcome.

It is now officially “Shop Tour” season. Clean up your shop because your shop may be on the next tour. Thanks to Doyle for coordinating this enjoyable activity. The best thing about the tours is the fact that everyone always picks up some ideas to apply in their own shop.

If you want to be on the tour list, contact Doyle.

Don't forget to take advantage of the forum. Instead of just “viewing” the

forum, you can ask questions or answer questions. It is a great way

to swap ideas and learn new tricks of the trade. You will be able

to share your ideas and experiences with other members through the

forum.

- A NOTE FROM YOUR TVW LIBRARIAN -

I'm sure everyone that has an interest in turning has noticed that

lately the Longworth Chuck has been shown and talked about a lot. If you

are interested in making a Longworth Chuck there is now an instructional

DVD in the Club Library. It's # 2112 and if you want to reserve the DVD

please contact me.

Let me remind you that our "in house" DVDs, such as the Longworth Chuck

DVD are available for viewing on the club website.

I will also remind you of a small change to the Club Library. Since our

"in house" DVDs are available on the website and since there are so many

of them, I have stopped bring them to the club meeting. Our commercial

DVDs and VHS tape will still be available at the meeting.

Henry, TVW Librarian

For a complete list of all items in the Digital Library, see Henry Davis

at club meetings, email him at hdavis37@charter.net or call him at

393-3191 and leave a message.

June

Meeting

June

Meeting

|

Bob Reese - displayed a music stand that he had created from walnut. |

|

Jay Hazel - had 3 bowls that he showed. One was of box elder with a natural edge, another was a very spalded bowl made from hickory, and the third bowl was a stave bowl, made from left over scrape wood. |

|

Henry Davis - showed a maple bowl but was actually explaining how the bottom ring was developed. |

|

|

Doyle McConnell - displayed a segmented bowl made from maple and a decorative band of spalded maple. |

|

Greg Myers - had created a pepper mill from several different types of wood. |

|

|

Ron Reimers - made 2 flutes from cherry wood and one from cedar. These had been turned on the lathe, which was a new experience for him. |

|

|

Karen Browning - showed several different pieces of wood with geometric designs on them that could be incorporated in segmented bowl turning. |

|

|

Newt Wright - showed a maple bowl that he had turned and explained the problems that he had in the process. |

|

|

Paul Jalbert - displayed a 4’ x 3’ pine wood relief carving that the Boy Scouts had all worked on. |

|

Tom Cowan - presented pictures of a walnut desk that he had made. This was a reproduction of a desk from around 1812-1814. This desk had 115’ feet of string inlay with numerous different inlays through- out the desk. The drawer construction details were very good. |

|

|

Geoff Roehm - showed a piece that he had created from an abalone shell for the TN National Guard. |

|

|

Jim Everett - showed some pictures of his completed project of a fireplace mantle that he had surrounded with his intarsia work. |

|

Dan Maher - showed pictures of a gun cabinet that he had created from oak and all the glass had been etched. |

To view the "Link of Interest" on our web site, please click here.

Craftsman 12" bandsaw, includes 8 extra blades and a couple of

fixtures. All for $175.00

Contact Henry Davis, 931-393-3191 or hdavis37@charter.net

Powermatic Model 64A contractor table saw for sale. It has the 30" accu-fence system. Has not been abused and looks great. $500.

Contact Chuck Taylor at taylorcw@bellsouth.net or 931-273-8886.

If you have woodworking items for sale or are looking for woodworking items, please send information to Chuck Taylor at 931-728-7086 or email to taylorcw@bellsouth.net .

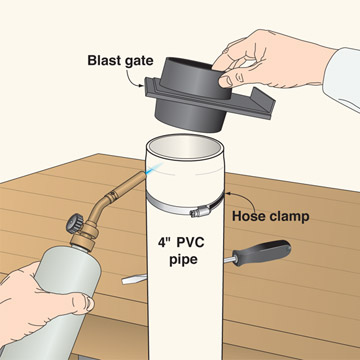

DOWNSIZE PVC TO FIT BLAST GATES

Shrink PVC pipe for your ductwork needs.

When installing a central ductwork system, a lot of people use 4"

PVC pipe instead of steel piping. But the inside diameter of the 4"

PVC is 1/8" too large for blast gates designed for steel ducts. This

problem can be solved by shrinking the PVC pipe slightly with a

propane torch.

To soften the PVC for the joints, slip a hose clamp over the pipe

and carefully heated the pipe until it softens. With the pipe end

soft, slip the blast gate into the pipe, slid the hose clamp up near

the end, and tightened it to snug-up the softened PVC end. Once the

pipe cooled and hardened, you can remove the hose clamp to use for

the next joint.

Finally, secure the blast gate to the pipe with a sheet metal screw.

With no tape, glue, or steel, and only a single hose clamp, it's a

clean, simple way to build an inexpensive but effective collection

system

------ Compliments of Wood Magazine "Daily Shop Tips" Website --------

Visit this web site for “tips for every situation”: http://www.woodworkingtips.com/etips/

The following companies are supporters of the TVW club. Click on their "logo" to go to their web site.