The March meeting will be at 7:00 pm on the 20th at the University of Tennessee Space institute, room H111.

The March program will feature

John Lucas, a member of the Tennessee Association of Woodturners.

John will be demonstrating and discussing

how to photograph your furniture and woodworking projects. He will point

out the “do’s and don’ts” in obtaining the best possible

photographs to show off you workworking projects

Come out and see what John has to share with us at the March 20th

meeting.

(becoming members at the February meeting)

Be sure to meet all of our new members and welcome them to the club.

|

|

John Duval ............. Estill Springs |

.JPG) |

Dwayne Carver ......... Manchester |

A workshop was held on Saturday March 10 at Tom

Cowan’s Artisan shop in Cowan. Six eager students attended the workshop.

Tom says; “I hope

the workshop will inspire someone to give inlaying a try”. Thanks to Tom

for conducting the workshop. We expect to see some "show and tell" items

begin to show up with "inlay" work.

Another “inlay” workshop will be scheduled in the future if there is

sufficient interest.

The 2012 "Shop Tours" are beginning. The first tour is scheduled for March 24 and will be in the Murfreesboro area. The shops that will be on the tour include Jay Hazel, Don Roundsavill and Ranson Jones. Everyone will meet at the Manchester Cracker Barrel for breakfast and then carpool to Murfreesboro. Details will be given at the March TVW meeting. There is always some tricks and techniques to learn. Come and have a good time.

The TVW Executive Committee met on February 28th to set the yearly calendar of events for the club. Click here to view the planned activities and events for this year.

More than 20 carvers showed up at Phil's shop on

March 3rd with great expectations for a wonderful day with tools and

wood in hand. A large

load of buckeye and basswood lumber was unloaded for their future

projects. As usual, everyone had a great time and learned a few things.

The carvers normally meet on the first Saturday of each month and work

on individual or group projects. Anyone interested in carving is welcome

to attend these monthly meetings.

Want to learn how to play a flute? Here is your

chance. Ron Reimers has started a “Flute Circle” at Tom Cowan’s

workshop. Not only will

members learn how to create Indian flutes but they will also be able to

learn how to play them. The next meeting will be March 27th at Tom

Cowan’s Artisan shop in Cowan. The meeting will begin at 1:00 in the

afternoon. Please bring a folding chair of some sort as we are in short

supply of seating.

If you don't have a flute, you will be able to use one of Ron's flutes.

Also try to bring some kind of percussion instrument.

Come with the idea of having fun with this.

Additional information concerning future meeting will be presented at

the next regular club meeting.

Scott Short found a procedure on the internet describing how to rejuvenate Ni-Cad batteries. He tried it and it worked. If you have old Ni-Cads and want to bring them back to life, contact Scott.

If

you have not tried the TVW forum, take the time to view all the great

information exchange that is happening. Go ahead and register and you

will see what you have been missing. Instead of just “viewing” the

forum, you can then ask questions or answer questions. It is a great way

to swap ideas and learn new tricks of the trade. You will then be able

to share your ideas and experiences with other members through the

If

you have not tried the TVW forum, take the time to view all the great

information exchange that is happening. Go ahead and register and you

will see what you have been missing. Instead of just “viewing” the

forum, you can then ask questions or answer questions. It is a great way

to swap ideas and learn new tricks of the trade. You will then be able

to share your ideas and experiences with other members through the

forum.

The club library is a great way to learn new

techniques and brush up on old ones. Henry has the library “open” at

each regular meeting.

Please remember that you can now view some of the club DVDs on line. Go

to the library listing on our club website and click on the

underlined titles.

For a complete list of all items in the Digital Library, see Henry Davis

at club meetings, email him at [email protected] or call him at

393-3191 and leave a message.

February

Meeting

February

Meeting |

|

Jim Everett- displayed five pieces of Intarsia that included a fish, a horse, an Indian and a deer. |

|

Tom Cowan- showed a picture of a walnut chair that he had made using ash strips that were weaved making the seat. |

|

Mickey Knowles- displayed 4 bowls that he had made 3 from spaulted maple and one from a walnut root. |

|

|

Doyle McConnell- showed a spindle that he had created for a person who was trying to replace an old spindle. |

|

|

Jim Van Cleave- displayed a carving that he had created of three leaves attached to a walnut board. |

|

|

Ross Roepke- displayed a walnut podium that he had created for one of the local churches. |

|

Larry Bowers – displayed a bed headboard that been created from a plan in Wood Magazine. Jim Van Cleave had helped him in his shop. |

|

Scott Tinker- displayed a sample offering bowl and a small lidded box that he had made from cherry along with a very large bowl that he roughed from a Chittam burl. |

|

Doug Dunlap- displayed a Longworth chuck, made at the club’s first workshop. |

|

|

Phil Bishop- displayed several pieces that he had turned and carved for an old bed |

|

|

Louis Bryant- had created a cherry pepper mill, along with a spaulted box elder bowl and a walnut bowl. |

|

Greg Myers-

displayed some wine bottle stoppers along with a

beer tap handle

that he had turned. |

To view the "Link of Interest" on our web site, please click here.

If you have woodworking items for sale or are looking for woodworking items, please send information to Chuck Taylor at 931-728-7086 or email to [email protected] .

DRILL PRESS: A tall upright machine useful

for suddenly snatching a piece of wood out of your hands so that it

smacks you in the chest and flings your drink across the room,

splattering it against that freshly-stained heirloom masterpiece, on

which you had just sprayed the last coat of finish and was just about

dry.

DRILL PRESS: A tall upright machine useful

for suddenly snatching a piece of wood out of your hands so that it

smacks you in the chest and flings your drink across the room,

splattering it against that freshly-stained heirloom masterpiece, on

which you had just sprayed the last coat of finish and was just about

dry.

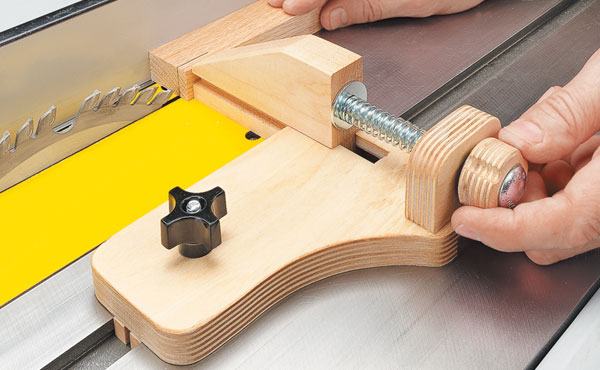

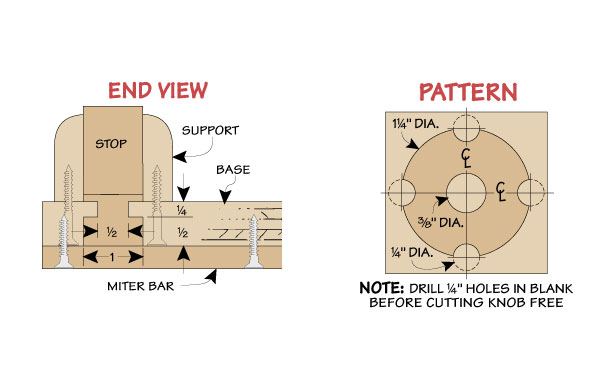

Cut Perfectly Sized Strips

(Micro-Adjust Ripping Jig)

Ripping consistent, thin strips on the table saw can be a

hit-or-miss proposition. This shop-made jig brings accuracy in

ripping to a whole

new level.

To use the jig, slide it adjacent to the saw blade so you can “zero

out” the stop against the blade. Then, pull the jig back just in

front of

the blade and lock it down.

Now, rotate the knob counterclockwise to dial in the thickness of

the strip you need to cut. Slide your workpiece and rip fence over

until

the workpiece contacts the stop.

Finally, you’re ready to make the cut. The great thing is; you can

make repeated rip cuts without a lot of setup or fuss.

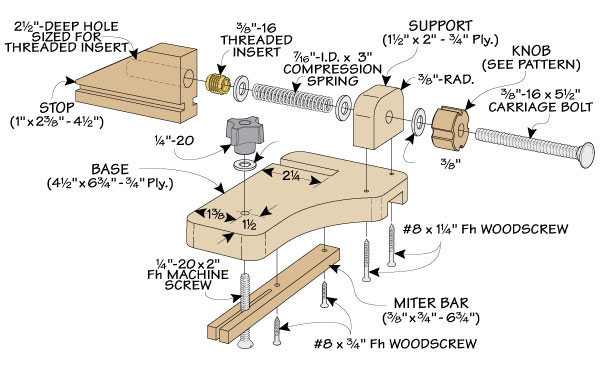

The drawings in this tip show how to make all the pieces, starting

with the base. A tapered stop slides along a slot in the base

controlled

by a shop-made knob and carriage bolt. The spring supplies constant

pressure on the workpiece.

------ Compliments of Wood Magazine "Daily Shop Tips" Website --------

Visit this web site for “tips for every situation”: http://www.woodworkingtips.com/etips/

The following companies are supporters of the TVW club. Click on their "logo" to go to their web site.