SPLINTERS

Tennessee Valley Woodworkers

Vol. 21/ Issue 1

January 2006

Editor: Chuck Taylor

Vol. 21/ Issue 1

January 2006

Editor: Chuck Taylor

Meeting Notice:

The next meeting of the TN Valley Woodworkers

Will be held, January 17th at 7:00 p.m. in the

Duck River Electric Building, Decherd, TN

All interested woodworkers are invited!

Please remember, in your thoughts and prayers,

all our Troops around the world and those on the way home.

The following people have agreed to serve as contacts for their particular

skills. If you have questions, suggestions for activities, or other

comments relating to these skills, please call these folks. Their

interest is to help the club better serve their area of expertise.

Your participation with them will help them achieve that goal.

Design: Tom

Cowan 967-4835

Finishing: Phil

Bishop 967-4626

Turning: Tom

Church 967-4460

Carving: Harry

May 962-0215

Sharpening: Bob

Reese 728-7974

Joinery: Ross

Roepke 455-9140

Maurice Ryan 962-1555

Health and Safety

List of Club Officers

President:

Loyd Ackerman

V. President: Tom

Cowan

Secretary: Bob

Lowrance

Treasurer: Henry

Davis

Publicity: Larry

Bowers

Newsletter Editor: Chuck Taylor

Web-Master: Richard Gulley

MEMBER INFORMATION

Club Dues

Club Dues are payable in January.

Our Dues are $10.00 for a single membership, and $15.00 for a family membership.

If you can't attend a meeting soon you can mail your dues check to

Henry Davis, 247 Delight Lane, Tullahoma, TN 37388.

MEMBER INFORMATION CHANGES

We strive to always keep the club

membership roster up to date. If you have changes to your home address,

phone number or email address please let us know so we can update our membership

list. Contact Henry Davis at 931-393-3191 or hdavis@cafes.net

WELCOME TO OUR NEW MEMBERS

Wayne Beam, Tullahoma

David and Yolanda Lacy, Winchester

THANKS

Thanks to Tom Gillard for his diligent efforts in publishing

the TVW Newsletter for the past eight years. He has done an outstanding

job and a great service to the club and members.

A special thanks to all the people who worked on the 20-year

Anniversary Celebration Dinner, making it a tremendous success for club

members and guests. The grand door prizes ($150 Woodcraft certificates)

were won by Ross Roepke and Dan Maher.

SHOW AND TELL:

Loyd Ackerman showed a video presentation of a Grandfather clock made for

his mother-in-law. The video showed various views and stages of completion

during the making of the clock case.

Tom Gillard brought two Sailboats,

one mounted to a natural edge base.

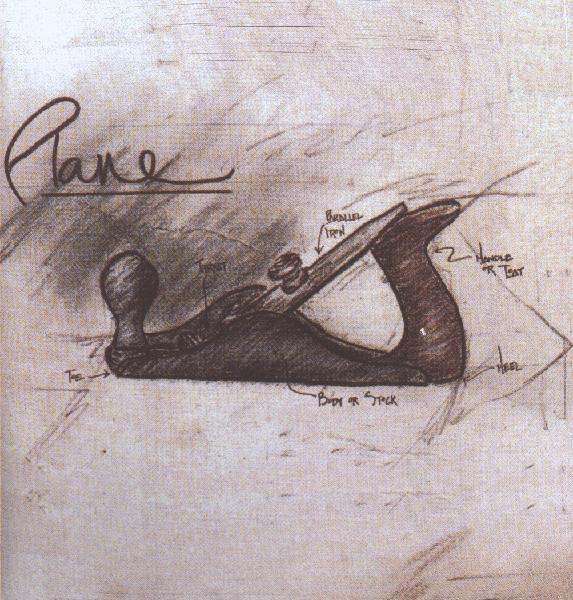

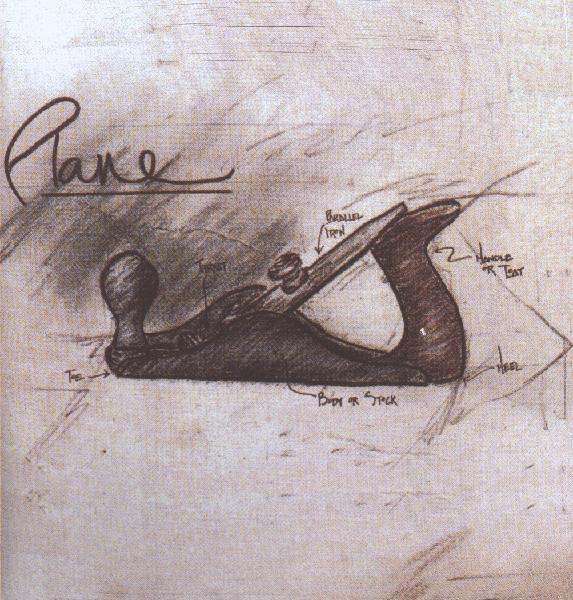

Ken Gould brought and discussed some very old detail trim planes

used

by his father.

Henry Davis showed a spalted maple bowl,

finished with sanding sealer and minwax.

Ross Roepke showed and discussed a solid mahogany table

with

curved legs. The drawer slides were made of poplar and the drawers had

“secret

compartments” hidden in the back. Ross discussed the difficulties encountered

in some of the manufacturing techniques. He also brought samples of crosses

he made for a church fundraiser.

Jim Acord brought and discussed a brochure from U-Bild, a supplier

of woodworking plans. Their web site is u-bild.com. He also brought and

distributed a booklet, “The Tree Book”.

Dick Wollam displayed a basswood carving

of flowers, a walking stick with very detailed

carvings and an owl carved from

western cedar.

Jack Rowe showed a small cherry table,

finished with Danish oil and coats of polyurethane on the top surface.

Mary Ellen Lindsay displayed her carving of a cup,

made of walnut.

Fred Heltsley brought and discussed a small

pipe rack with clay pipes.

Bob Lowrance brought a “Santa”

carving he had carved while attending the John C. Campbell School.

Billy May brought a basswood bull

he carved for a friend.

Bob Leonard showed items he had

made over the years. They included a knife, carvings of a dog, ax &

stump and cowboy boots. He also discussed two books for beginning carvers.

Wayne Beam brought two pedestal stands.

One was the first one he built and the other was the last one he finished.

Jim Van Cleave discussed his experience in cutting wax candles on his

bandsaw. The job left a major buildup of wax on the blade and the saw would

not run. He also discussed the accident he had during the cleaning of the

blade and the guide bearings (cut his finger).

Basswood

Among the most

important of America's nectar-producing trees, the basswood makes itself

at home along city streets as well as in the forest. In cityscapes, nurserymen

call the hardy, decorative tree American linden. But in the woods, it's

basswood, beetree, lime, or whitewood. Regardless of its name, basswood

has proven its value. Indians of New York state's Iroquois nation carved

ceremonial masks from the sapwood of living basswood trees, then split

the green-wood masks from the trunk. The gummy inner bark provided bandages.

And from its dried fibers they wove rope.

Among the most

important of America's nectar-producing trees, the basswood makes itself

at home along city streets as well as in the forest. In cityscapes, nurserymen

call the hardy, decorative tree American linden. But in the woods, it's

basswood, beetree, lime, or whitewood. Regardless of its name, basswood

has proven its value. Indians of New York state's Iroquois nation carved

ceremonial masks from the sapwood of living basswood trees, then split

the green-wood masks from the trunk. The gummy inner bark provided bandages.

And from its dried fibers they wove rope.

Beekeepers even today appreciate the quality of basswood-derived honey.

In summer, the tree's fragrant flower clusters provide a strong-flavored

nectar. Basswood stock also becomes the very boxes in which the honeycombs

are stored and shipped.

Carvers prefer basswood because it holds detail well, doesn't split,

has straight-grain, and carves easily. They usually prefer air-dried, slow-grown

northern stock. Basswood also can become drawer stock, hidden furniture

parts, and painted items. In industry, it plays a role as boxes and food

containers. As veneer, it can underlie fine cabinet woods in plywood. This

light, versatile wood also works for picture frames, toys, and millwork

such as window sashes. It even makes fine turning wood.

It would be hard to find a wood more perfect for carving. A sharp knife

or gouge slides through it as if cutting butter. And the finish of a clean

cut looks lustrous.

· Because basswood takes fine detail, it's great

for relief, figure, and chip carving.

· Basswood requires control or your carving tool may go further

along a stroke than planned.

Additional information about basswood:

· Basswood's low-hardness rating makes it ideal for hand tools.

· Power planing basswood poses no problems. You'll find jointing

effortless, too.

· Because the wood is dense, ripping requires a rip-set blade

with 24 teeth or less to avoid burning. In crosscutting, it won't tear

out or chip.

· Use sharp bits and don't rush the router when shaping basswood,

as its tight grain and density does tend to burn (although burns easily

sand off).

· Unlike some other lightweight, straight-grained woods (such

as redwood), basswood fastens well with nails or screws. And it's not necessary

to predrill.

Sanding basswood proves to be a soothing, smoothing task. But when

it comes to staining, blotching can result. If uneven staining appears

on a test piece, apply wood conditioner before staining. Remember, though,

even wood conditioner won't subdue discolored streaks in the wood.

Wood-Online

Shop Tip of the Day

A piece of pipe makes button sanding a cinch.

Wooden buttons often need to be sanded before use. But it's sure tempting

to stick them into place without sanding because they're so hard to hang

on to. Push the stem of the button into the end of a piece of copper or

plastic pipe about 12" long to give yourself a better grip. Try different

sizes of pipe and tubing for various buttons.

--From the WOOD magazine shop

Web Sites of interest.

Wood Central

See you on the 17th.

click on the image to go to these sites

Special contributors to Club functions

Vol. 21/ Issue 1

January 2006

Editor: Chuck Taylor

Vol. 21/ Issue 1

January 2006

Editor: Chuck Taylor

![]()

![]()