SPLINTERS

Tennessee Valley Woodworkers

Vol. 20/ Issue 3

March 2005

Editor: Tom Gillard Jr.

Vol. 20/ Issue 3

March 2005

Editor: Tom Gillard Jr.

Meeting Notice:

The next meeting of the TN Valley Woodworkers

Will be held, March15 th at 7:00 p.m. in the

Duck River Electric Building, Dechard, TN

All interested woodworkers are invited!

The following people have agreed to serve as contacts for their particular

skills. If you have questions, suggestions for activities, or other

comments relating to these skills, please call these folks. Their

interest is to help the club better serve their area of expertise.

Your participation with them will help them achieve that goal.

Tom Cowan

967-4835 Design

Phil Bishop

967-4626 Finishing

Tom Church 967-4460

Turning Harry

May 962-0215

Carving

Bob Reese

728-7974 Sharpening Ross

Roepke 455-9140 Jointery

Maurice Ryan 962-1555

Health and Safety

List of Club Officers

President:

Loyd Ackerman

V. President: Tom

Cowan

Secretary: Chuck

Taylor

Treasurer: Henry

Davis

Publicity: Larry

Bowers

Newsletter Editor: Tom Gillard

Jr.

Please

remember, in your thoughts and prayers, all our Troops around the world and

those on the way home.

Calendar

of Events

April 15-17: Dogwood Festival –Winchester

May 14:

Turning Bee –– Winchester

April 21:

Picnic –– Belvedere Falls Mill

September

19: CC Fair –– 24 Manchester

October:

Fall Seminar –– To Be Determined

December 9th:: Holiday

Party / 20th: Anniversary celebration at American Legion in

Tullahoma.

Show

& Tell

Ross Roepke: brought an oak table

and explained the details of how he made the front section. The front, including

the drawer fronts, were made from one single piece, making the entire front

section matching in grain pattern. He also showed a

cross he had made for the church

Jim Van Cleave displayed a walnut

relief carving of a vine. He also brought a bed

headboard of his own design, finished with varnish. He had carved rosebuds

on the posts. The walnut came from his grandfather’s farm.

Steve Shores brought some mahogany

spoons that he had made and a mirror he

turned, with a decretive carving on the back

Dick Wollam brought and discussed a yellow

pine carving of a duck painted with

acrylic.

Loyd Murphy brought two

goblets made from green cedar.

Tom Cowan showed and discussed a scrapbook

put together by John Sargent. The scrapbook was a collection of projects John

had made over the years.

Chuck Taylor brought a bowl made from box

elder. He also brought a bed and a chair

from a set of doll furniture being made for his granddaughter’s third

birthday.

Library Project

Franklin County Library: The cabinets are

installed. Take a look at them. This is another reason we

should be proud of our Club.

Pic_1

Pic_2

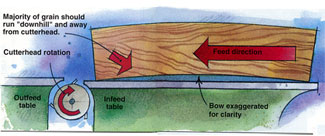

How to edge-joint bowed stock

It's a basic woodworking rule: Boards need one

straight edge before you can work with them. If your board is warped by less

than 1/2" or so, it's simple enough to power up a jointer and straighten

the edge. But when you're faced with a seriously bowed work piece, try the

tricks here to straighten things out.

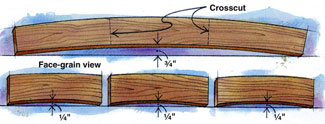

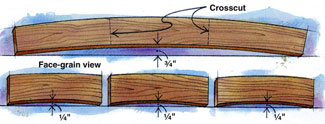

1. Before you joint a board that's bowed by more than 1/2" along its

length, cut the board to shorter lengths, if possible. This may reduce the bow

of each work piece to 1/2" or less, allowing you to straighten the work

pieces with your jointer in the typical fashion. And, you'll get more usable

stock out of the board. In the example below, a board with 3/4" bow

yields three boards each with 1/4" bow.

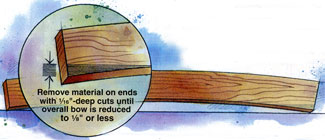

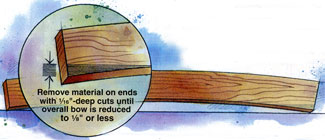

2. If you can't cut your board to shorter lengths,

use this method to joint long, bowed stock. (We do not recommend you try this

procedure with work pieces longer than 6' if you have a 6" jointer, or

longer than 8' if you own an 8" jointer. For these pieces, use the

procedure described in Step 4.)

First, set your jointer for a 1/16" cut.

Then, place your board on the jointer infeed table with its concave edge down.

Make several passes on one end of the board. Each pass should remove more

material along the edge than the pass before it. As the jointed surface of the

edge approaches the center of the board, turn the board around and repeat this

procedure on the other end. The jointed edges should nearly meet in the center.

By this point the overall bow should be less than 1/8", shown below.

Make one or two complete passes to straighten the edge.

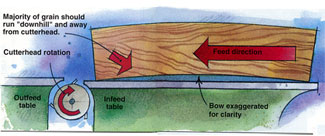

3. Next, read the grain of the board to determine

which end to feed first so the grain runs "downhill" and away from the

cutter head, as shown below. This helps reduce grain tearout.

Now, decrease the cutting depth to 1/32", and

make a final pass along the entire edge of the board. If the grain runs every

which way, slow down your feet rate to reduce tearout to a minimum.

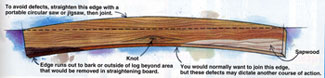

4. For boards too long for the method described in Step 2, or for short boards

bowed 1/2" or more, try this technique. With a straightedge or chalk line,

mark a line as shown at right. Then, cut along this line with a portable

circular saw or jigsaw. If you closely follow the line you should be able to

joint the edge straight and smooth in one pass, as described in Step 3.

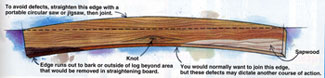

5. Because of the position of defects in a board, you may find it necessary to

straighten its convex edge. This could happen when the best wood in a board is

along its convex edge, as shown below. Then, it often makes sense to

straighten that edge first so you can join the good edge to other work pieces or

rip thin strips from the best wood and work toward the lesser-quality wood.

Do not attempt to straighten a convex edge on a jointer, even if the convex edge

is bowed by less than 1/2". To straighten any convex edge, follow the

method described in Step 4.

More joining pointers to keep in mind

The grain of highly figured woods, such as

bird's-eye maple, can tear out quite easily, especially if your jointer knives

aren't as sharp as they should be. At these times, slow down your feed rate to a

crawl (just an inch or two per second) and take light cuts (1/32" or less).

It may be difficult to tell if you're getting a

complete cut at these shallow depths, so try this trick. Mark a wavy pencil line

along the entire edge, as shown right, and make the cut. Any remaining

pencil marks tell you that you need to repeat the cut.

Here's

a good rule of thumb that may actually save your thumb. Whenever you

edge-joint a board that is not as wide as your jointer's fence is high, use a

push stick, as shown at right.

Here's

a good rule of thumb that may actually save your thumb. Whenever you

edge-joint a board that is not as wide as your jointer's fence is high, use a

push stick, as shown at right.

Remember to reposition your jointer's fence across

the width of the tables from time to time. You'll get more life from your knives

because they will wear more evenly along their lengths.

Written by:

Bill Krier with Jan Svec

Illustrations:

Brian Jensen

Wood

On-Line

The Club will be selling tickets for two

raffles to be held at the Club picnic on May 21 at Falls Mill.

Items to be raffled are the Delta Dust Collector donated by the

Delta development team that did the program in February and a Jet

Mini Lathe donated by General Industrial Supply. Tickets will be

on sale at the Club meetings in March, April, and May and again at

the picnic itself. Consider this as a donation to the Club with a

chance to win a great prize.

Tickets will be available for $3 each or

2 for $5 to Club members and guests. There will be two boxes. One

for white tickets and another for red. Purchasers are to write

their names on the back of the ticket half to be put into the

appropriate box. You do not need to be present to win.

Funds from the raffles will be put into

the Club treasury and earmarked for purchase of audio/video

equipment and support of Club celebration events.

Larry Bowers will be selling the tickets.

THIS MONTH

The program this month will be presented by Mr. Wayne Souter, from the Woodline

USA company located in LaVergne, TN. He will be showing and

demonstrating his precision dovetail joinery system

See you on the 15th.

click on the image to go to these sites

Vol. 20/ Issue 3

March 2005

Editor: Tom Gillard Jr.

Vol. 20/ Issue 3

March 2005

Editor: Tom Gillard Jr.

![]()

![]()

![]()

![]()

Here's

a good rule of thumb that may actually save your thumb. Whenever you

edge-joint a board that is not as wide as your jointer's fence is high, use a

push stick, as shown at right.

Here's

a good rule of thumb that may actually save your thumb. Whenever you

edge-joint a board that is not as wide as your jointer's fence is high, use a

push stick, as shown at right.