SPLINTERS

Tennessee Valley Woodworkers

Vol. 18/ Issue 9 September

2003 Editor: Tom Gillard Jr.

Vol. 18/ Issue 9 September

2003 Editor: Tom Gillard Jr.

Meeting Notice:

The next meeting of the TN Valley Woodworkers

Will be held, September 16th, at 7:00 p.m. in the

Duck River Electric Building, Dechard, TN

All interested woodworkers are invited!

The following people have agreed to serve as contacts for their particular

skills. If you have questions, suggestions for activities, or other

comments relating to these skills, please call these folks. Their

interest is to help the club better serve their area of expertise.

Your participation with them will help them achieve that goal.

Design: Alice

Berry

454-3815

Finishing: Phil

Bishop

967-4626

Turning: Tom

Church

967-4460

Carving: Harry

May 962-0215

Sharpening:

Bob

Reese

728-7974

Joinery: Ross

Roepke 455-9140

Health and Safety:

Maurice

Ryan 962-1555

List of

Club Officers

President: Doyle

McConnell

V. President: Ken

Gould

Secretary: Barbara

Keen

Treasurer: Henry

Davis

Publicity: Loyd

Ackerman

Newsletter Editor Tom Gillard

Jr.

GOD BLESS AMERICA!

Please remember, in your thoughts and prayers, all our Troops heading

for the Middle East.

FOR MEMBERS ONLY

Don't forget about the club give-away this year.

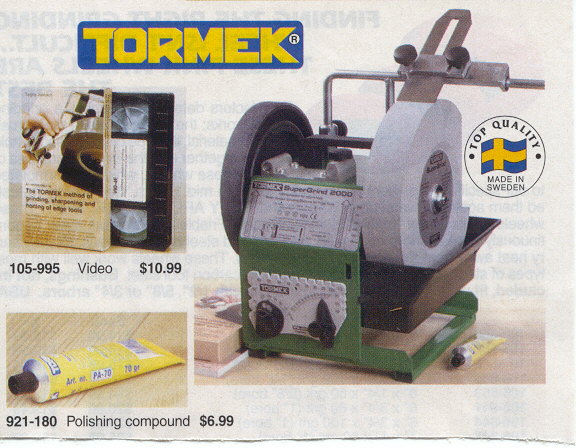

We have a Tormek sharpening machine for some lucky winner at the Christmas

party.

Coffee County Fair

The fair date is Sept. 15 through 20-- . TVWW has a building in the

Morton Village section of the fairgrounds. Morton Village is behind

the livestock barn and the main arena area. We will be exhibiting

and demonstrating there during the week but will have a concentrated effort

on Friday and Saturday (19th & 20th). Click HERE

to visit the fair.

EVENTS:

Gruetli-Laager Great Outdoors events happens on Oct 17 & 18.

WELCOME NEW MEMBER

We welcome Dick Wollam to the club, Dick is from Winchester and says

he has many woodworking interests.

Great that you joined us Dick!

September Program:

The program this month will be on making and decorating bandsaw boxes and

will be presented by Ray Torstenson.

The Fall Seminar, “Laws of Woodturning” has been scheduled for October

25, 2003. Subject matter offered will be both basic and intermediate

from the artistic and practical application. Also, included will

be the importance of determining the speed of the lathe. Loyd’s example

of the “exploding bowl” emphasizes the need for correct speed. The

location of the class and more details of the seminar will be forthcoming.

DID YOU KNOW ?

As of this month we have

137 members in the TVW, 33 of those have joined us in the past

year, if my math is correct that's almost a 25% increase.

So far this year our attendance

at our meetings has averaged 62 members, this count is from our grand door

prize sign-up sheets and doesn't count our guest.

Our all time attendance

record was in March 2003 with 70 members and 9 guests. Wow that was

a roomfull !

Way to go TVW !

Tip of the Month

After I stained one side of a

paneled door, I was looking for a

way to hold it so I could stain the

other side. Because I had

mitered the corners of the door

frame, I had some triangular

cutoffs in my scrap bin that were

just what I needed.

The triangular scraps support the piece being stained only on

their "peaks". Drilling holes in the cutoffs and inserting a dowel

helps keep

the blocks from tipping over. You can adjust this simple jig for any

width

project by sliding the blocks along the dowel. For larger pieces,

simply use a longer piece of dowel.

—Norman Crowfoot, Tucson, Ariz.

-------------------------------------------------------

Taken from the "Woodworker's

Guild of Georgia" newsletter

+ + + + + + + + + + + + + + + + +

I would like to talk about shop first aid kits. If you don't have one,

do yourself a favor and get one before you use your shop again. In March

of this year, I responded to a question about first aid kits on the Guild

web site message board. I said that my kit consisted of some 4x4 gauze,

tape and band-aids. I said this is all you need because you should never

put yourself in a

position to get seriously injured, such as cutting off body parts so

the items in my kit should be all you would ever need.

After reading some other responses by Mike Schwarz, Tom Wilkinson,

Jim Dillon and Mike Campbell, who asked the question in the first place,

I realized how wrong I was. — not about never putting yourself in a position

to cut off body parts, but about not needing other items in a shop first

aid kit.

Here are some suggestions of what to include in your kit:

· Small mirror (to see how to get objects out of eye)

· 2x2 and 4x4 gauze pads

· 3M transpore tape (to reinforce Band-Aid in certain spots)

· Saline spray (for removal and soothing of dust in the nose)

· Eye wash

· Ace bandage (for sprains or use as a tourniquet)

· Instant ice pack

· Tweezers (for removing splinters)

· Magnifying glass or glasses (for removing splinters)

· Triple antibiotic ointment

· Assorted Band-Aid

· Tape

· Hydrogen peroxide

· Telephone number of favorite E.R. — if need arises, call ahead

so they

will be able to prepare for your arrival

· Large zip lock bag — if you ever cut off a body part, you

can put it on

ice and put in zip lock bag and take to the E.R with you so it can

be re-attached

· Fire extinguisher. — something we often don't think about,

but equally

important.

We need to have a main power cut off switch near the door. In an emergency,

you can cut off all power in shop in case of fire or other disasters. We

hope you never need any of these items, but it’s comforting just knowing

they are there in your shop, if the need ever arises.

**************************************************

Oldham Tool Co

I want to thank Paul Serina from the Oldham

Tool Co. for the wonderful items that he donated to the club for a

giveaway. I was over in W. Jefferson, NC last month and paid a visit

on Paul. It is amazing how many people are involved in making a router

bit or saw blade. I’ll try and put together a story for everyone

by next month’s newsletter. If any of you readers are looking for

some quality tooling or your router or saw, give Oldham a chance.

***********************************************************************

SHOW AND TELL:

Maurice Ryan brought in a really

old violin that he played as a child a long time ago. It had

many cracks and was in very poor condition and he asked Bob Reese to look

at it and tell him if it was worth fixing. It was and Bob fixed it

and Maurice showed pictures of before it was fixed and after it was fixed

and the violin not only looks good now it also sounds good.

James Coulson made a table that

was featured in last months Wood Magazine. He made it out of Cherry

and mixed two different colors of stain to get the color he wanted and

than finished with Deft.

Ray Cole brought in pictures of a kitchen he renovated for customers

of his.

Doyle McConnell brought in a large

natural edge bowl turned out of Wormy Red Maple.

Henry Davis brought in a gadget that he made after seeing and using

one at Maurice’s shop. It was a piece of plywood with a saw blade

cut in the edge, so you can fit it over your saw blade when changing blades

and prevent it from moving when you are tightening or loosening the blade.

Jim Van Cleave brought a work in process. It will be a

tilt top table with pedestal and 3 legs with ball and claw feet.

It has a birdcage to hold top and the top are made out of Black Walnut

with scallops around its edge. He had some of the scallops carved

and sanded and others to do yet. The top is 27 inches and he made a fixture

with 3 rollers on it and put his router on sled and held rotor in place

and turns table by hand and kept changing position until he had it the

correct size. He also used the rotor to put a cove all the way around

it. He drew the lines where he wants the scallops with a template

and used a Dremel tool to cut away some of the scrap and than carved the

rest.

Gary Runyon found a use for some of his scrap Cherry wood he made Cherry

boxes with sliding tops. He used minwax and Teac oil to finish

them putting it on with steel wool size 0000. He also turned a darning

egg; small weaving needles and a Cherry threaded box for the needles. He

finished the inside of the boxes before he glued them.

Harold Hewgley turned a vase

out of Palonia Royal Princess wood. He finished it with high gloss

polyurethane.

Bob Lowance carved an Indian Mask and he also went to John C. Campbell

Folk school and he carved a cowboy

and a Santa. He finished the mask with oils and linseed oil and

all the carvings were made from BassWood.

Dave Whyte showed a bending brake

he made for bending metal and this was not made out of his usual Walnut

since he ran out of Walnut. He also made a bending jig for flat metal

and it did have walnut on the ends of it.

Harry May carved a dogs head on

a piece of wormy Buckeye and put on a walking stick. He carved another

walking stick with an English

Bull Dog’s head and an owl, snake, turtle and upside down sea horse

and a wood spirit carved in it. He also showed a

mule that he carved.

Bob Reese made a violin out

of Birdseye Maple which took him a year to finish. The Maple was

in the shop for about 45 years. His wife played it and it sounded

very good. He also made a tool

sharpener based on the Wolverine sharpener. He made it mostly

out of wood and said it was very easy to make.

Loyd Ackerman went to Norway

last month and wanted to bring back sample of type of bowls they turn but

they were to expensive. He did bring two bowls that he turned out

of Black Walnut. His wife had purchased a plant stand she liked and

after seeing it he decided to make one like it, his was made out of Walnut

with the center of the top made out of marble. He did everything

but the legs on the lathe.

Newton Wright 12 years ago found a book of musical instruments and out

of it he made a Mountain Teardrop fiddle.

He carved the end of neck for an image of his dog. He also made a

Spill Plane like he saw on the Wood Wright program. You make peels

of wood from it to start a fire with.

Ross Roepke brought in a picture of a solid Mahogany modern bed design

that he is making. It uses full 2-inch thick pieces of Mahogany to

make it. The original cost $3200.00 and the wood to make his has

cost him $300.00. He cut some of the pieces for it and has about 5 hours

work in it so far.

^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^

Stones River Woodworkers Club will meet at the Farm Bureau Insurance Building,

818 S. Church Street (Highway 231) Murfreesboro, TN at 7:00 PM. The

Stones River Woodworkers will have their September. meeting on 9/23/03.

Harry Hodge, Stones River Woodworkers Club

FOR SALE

(Click here for

pictures)

Sears: 6 x 48" belt / 9" dia. disk sander

Comes with a few extra disks

It has the stand to go with it.

Contact: Tom Gillard

Jr.

455-6651(H), 393-0525(W)

$125.00

10 % OFF Fine Woodworking

Books from Taunton Press

…We’re open Monday thru Saturday

click on picture to visit Oldham

SEE YOU ON THE

16th!

Vol. 18/ Issue 9 September

2003 Editor: Tom Gillard Jr.

Vol. 18/ Issue 9 September

2003 Editor: Tom Gillard Jr.