SPLINTERS

Tennessee Valley Woodworkers

Vol. 17/ Issue 11 November

2002 Editor: Tom Gillard

Jr.

Vol. 17/ Issue 11 November

2002 Editor: Tom Gillard

Jr.

Meeting Notice:

The next meeting of the TN Valley Woodworkers

Will be held, November 19th, at 7:00 p.m. in the

Duck River Electric Building, Decherd, TN

All interested woodworkers are invited!

The following people have agreed to serve as contacts for their particular

skills. If you have questions, suggestions for activities, or other

comments relating to these skills, please call these folks. Their

interest is to help the club better serve their area of expertise.

Your participation with them will help them achieve that goal.

The following people have agreed to serve as contacts for their particular

skills. If you have questions, suggestions for activities, or other

comments relating to these skills, please call these folks. Their

interest is to help the club better serve their area of expertise.

Your participation with them will help them achieve that goal.

Alice

Berry 454-3815 Design

Phil Bishop

967-4626 Finishing

Tom

Church 967-4460 Turning

Harry May

962-0215 Carving

Bob

Reese 728-7974 Sharpening

Ross Roepke

455-9140 Joinery

Maurice Ryan 962-1555 Health and Safety

List of

Club Officers

President: Bob Leonard

V. President: Doyle McConnell

Secretary: Barbara Keen

Treasurer: Henry Davis

Publicity: Maurice & Ruth Ryan

Newsletter Editor: Tom Gillard Jr.

GOD BLESS AMERICA!

We are getting a new home for the newsletter...

Richard Gulley is spearheading this effort in hopes that we can catalog

more of the things that we woodworkers like. Nothing else about the newsletter

will change. Click HERE to go

to the new address for all things concerning the Tennessee Valley

Woodworkers.

Thanks,

CALENDAR of EVENTS

- Christmas Potluck - December 6th at the First Church of the Nazarene

Fellowship Hall, address: (4th & Cumberland). I'm

sure we'll discuss the Christmas pot-luck at our next meeting. We've been

asked to bring a little something from the shop to use for door prizes

- Look around and see what you have. We'll also need to know how many to

plan for, so take a count of family and guests that are planning to attend.

We'll try to get a total at the November meeting.

The November meeting will be a program by Tom Gillard on

glue. This presentation is to complement the joinery theme we have

covered this year. Tom is a professional woodworker and owner of Branching

Out a Tullahoma business.

Elections are coming up soon!

If the nominating committee calls you and asks you to serve, PLEASE consider

it. They wouldn't have asked you if they didn't believe you would

do a good job.

ANNOUNCEMENTS: Steve Savelle said that he had gotten a lot of

basswood from a friend and anyone that could use some should contact him

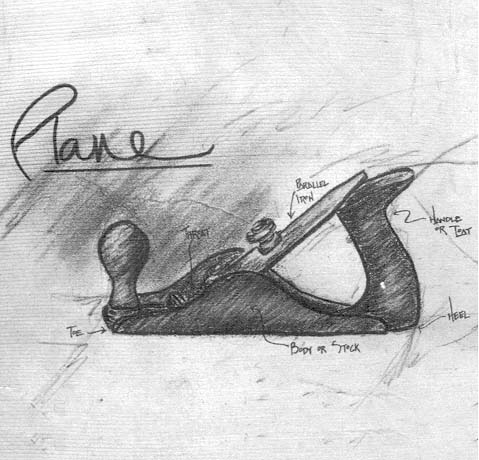

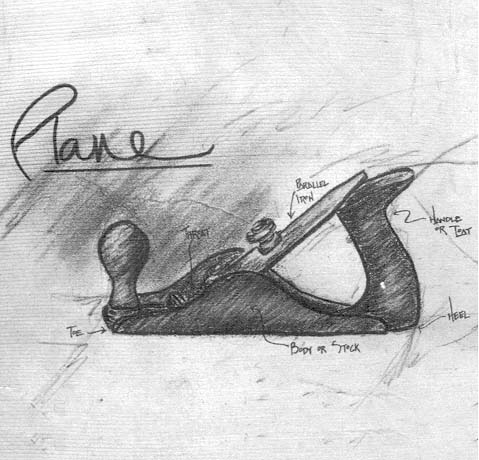

Yesterday's Tools: Crown Molder

This yellow birch crown molder dates back to the late 1700s. A furnituremaker

probably used molding of this size and style.

Craftsmanship was on the rise in the prosperous English colonies of

North America by the middle of the 18th century. Many colonists, enjoying

affluence after struggling to civilize the new world, sought more refined

surroundings.

Colonial carpenters and furnituremakers obliged them with English-style

work, featuring ornate moldings. The largest were crown and cornice moldings.

Crown molding fits on an angle across the junction of the wall and ceiling

inside a building; cornice molding, where the roof overhang meets the outside

wall. Similar moldings also graced cabinetry and even picture frames.

To make these fancy moldings, carpenters and furnituremakers used crown

molders—sometimes called cornice planes—like the one shown above. The crown

molder's curvaceous blade usually measured 3–4" wide, but some were as

wide as 8". The blade of the crown molder shown measures 3-1/8" wide. The

plane's body is 3-1/2" wide and 12" long.

In practice, woodworkers didn't start on flat stock with these wide

planes. The general form of the molding would be roughed out first, using

adzes, gouges, and smaller molding planes. Only then would the craftsman

bring out his big crown molder.

As often as not, a master and apprentice would team up to plow the wide,

deep blade through the wood. The master guided the plane as the apprentice

tugged on a rope tied to an eye screwed into the plane's front. (Though

the eye is long gone from the plane in the photo, you can see the hole

for it in the front of the plane.) Though it sounds simple, the actual

procedure was anything but a romp in the shop. Often, the planing was accompanied

by much hot-tempered give-and-take between the master and his apprentice.

Surviving crown molders date as far back as the mid-1700s. Some were

made as late as the 1890s, but machine-milled moldings, which became common

after the Civil War, finally ended the reign of the crown molders.

Because cornice planes and crown molders were tools of master craftsmen,

they were uncommon items. That also means most didn't suffer neglect and

abuse, so surviving tools are often in very good condition.

Today, collectors covet these fancy molding planes. "Marked 18th century

models can be worth $2,000–$3,000," according to antique-tool collector

and dealer Philip Whitby. "A pair of early Philadephia crown molders, one

with a blade more than 6" wide and the other more than 7", sold lately

for $10,000," he reports.

(Wood On-line:

http://www.woodmagazine.com//11-1-02.html)

SHOW AND TELL:

Jim Van Cleave brought a Walnut table for maps that he put together

to show how it was done.

Richard Gulley brought wooden spoons he had made, 2 of which were put

together with a wooden chain with each of his daughters names on them.

Tom Gillard Jr. showed a turned pen that were a gift for the Boy Scout

adult training course. There were 80-85 made. He also showed an octagon

top of a game table he made out of quarter-sawed oak with a tar stain and

a checkerboard in the center.

Loyd Ackerman brought a lamented curve piece that was made out of 5

– 1/8 inch pieces of door skin and with veneer lamented on each side.

He said it was from a program Ray Cole had given on curved pieces about

7 years ago. He also showed a box he made out of Mahogany and said

he found out the hard way that you have to lower your pressure on pneumatic

guns when using on Mahogany or they would blow a hole through the piece

as he did.

Harold Hewgley showed a chip and dip bowl he made out of Cherry and

sprayed with a water based acrylic.

Henry Davis made a keepsake box that had a drawer in it and was made

out of maple with a spalted maple top. The lid has a space for letters

or pictures.

Bob Beswetherick brought back his finished Mandolin made out of Spruce

for the top, Canary wood, yellow heart, purple heart and popular.

He finished with Tongue oil. The second Mandolin he brought in was

made out of spruce, popular, African mahogany, yellow heart, Purple Heart

and canary wood. He has 100 hours in each instrument.

Dave Whyte made 2 holders

for

scrappers. He made the brass adjustment by using a ¼-20 screw

and epoxy on a brass knob. They were made out of oak and as usual they

were both functional and pleasing to the eye.

Dave Whyte made 2 holders

for

scrappers. He made the brass adjustment by using a ¼-20 screw

and epoxy on a brass knob. They were made out of oak and as usual they

were both functional and pleasing to the eye.

John Brewster our newest member turned a bowl out of cherry. He

also made a bowl out of Dogwood.

Karen Kerce turned a bowl out of spalted maple and another out of Cedar

that would have been firewood if she had not rescued it.

Doyle showed

a vase he had turned out of Box Elder. The finish was gloss polyurethane

thinned with Mineral Spirits 60/40 and wiped on while lathe was turning.

He let dry between coats

Doyle showed

a vase he had turned out of Box Elder. The finish was gloss polyurethane

thinned with Mineral Spirits 60/40 and wiped on while lathe was turning.

He let dry between coats

John Mayberry made a stool out of cherry for his daughter and he weaved

the seat at the fair.

John Sargent brought

in a guitar he made from a kit. It was Rosewood, Spruce, Ebony, and

Mahogany. A second guitar was shown that was made by Earl George

completely out of maple

John Sargent brought

in a guitar he made from a kit. It was Rosewood, Spruce, Ebony, and

Mahogany. A second guitar was shown that was made by Earl George

completely out of maple

Sweet Gum

In the old days, youngsters throughout the rural South went to the

woods, not the grocery store, for their chewing gum. There, they sought

out a tree with unusual star-shaped leaves and bark resembling alligator

skin. From it they pried off, then popped into their mouths, yellowish

brown balls of a fragrant, resinous substance with a licorice-like taste.

Their treat was the sap of the native sweet gum tree (Liquidambar styraciflua).

Little did they know that this natural confection, called liquidambar,

had been in demand for centuries.

As reported by historians traveling with the explorer Cortes in 16th-century

Mexico, the Aztec emperor Montezuma relaxed by puffing a cane stuffed with

a mixture of tobacco and a flavoring of liquidambar from a tropical variety

of sweet gum. But even before that, in Europe, liquidambar was obtained

through Asian traders for use in perfume, incense, and for treating diphtheria

and flatulence.

Despite the world demand for liquidambar through the centuries, little

was done with the yield of the North American sweet gum tree. It did serve

as a curative for Confederate soldiers' dysentery, and was harvested during

the Second World War when Asian supplies were cut off.

Sweet gum wood, though, has been another story. The often beautifully

figured stock can resemble walnut. And when quartersawn, it passes as the

costly Circassian walnut fancied for fine furniture and gunstocks.

(Wood Online)

FOR SALE

Craftsman 10 in. Table Saw $250.00

Craftsman Wood Shaper $175.00

14 Shaper Cutters $100.00

Central Machinery 8 in. grinder $75.00

Contact Henry Davis

393-3191

FOR SALE:

12” Sears Wood Turning Lathe.

36” between centers, ½ hp motor, 4 speeds;

Comes with the following items:

6” & 12” tool rest, 4” faceplate, table and a speed reduction

assembly.

$150.00

Contact Tom Gillard (455-6651

or 393-0525)

FOR SALE:

Heavy duty wood turning lathe, 18 3/4" swing, 35" between centers,

made by J.A. Fay in

Cincinnati in early 1900's, on heavy timber frame, 3/4 hp single

phase motor,

3 different length tool rests, two faceplates, can be rigged for

outboard turning, labor intensive, not for sissies,

$250.00

Contact: Jim Van Cleave

455-8150

WEB

SITES of INTEREST

Members sites:

Resourse Sites:

The Leitz Tooling Systems has moved to Muscle Shoals, AL but

will still do the sharpening. The blades will have to be shipped

UPS as the

salesman doesn't call on me as much now that the company has moved.

This cost will have to be passed along. Sorry.

Call (393-0525) or stop by for details.

10 % OFF Fine Woodworking

Books from Taunton Press

…We’re open Monday thru Saturday

SEE YOU ON THE

19th!

Webmaster:

Tom Gillard Jr.

Vol. 17/ Issue 11 November

2002 Editor: Tom Gillard

Jr.

Vol. 17/ Issue 11 November

2002 Editor: Tom Gillard

Jr.

Dave Whyte made 2 holders

for

scrappers. He made the brass adjustment by using a ¼-20 screw

and epoxy on a brass knob. They were made out of oak and as usual they

were both functional and pleasing to the eye.

Dave Whyte made 2 holders

for

scrappers. He made the brass adjustment by using a ¼-20 screw

and epoxy on a brass knob. They were made out of oak and as usual they

were both functional and pleasing to the eye.

Doyle showed

a vase he had turned out of Box Elder. The finish was gloss polyurethane

thinned with Mineral Spirits 60/40 and wiped on while lathe was turning.

He let dry between coats

Doyle showed

a vase he had turned out of Box Elder. The finish was gloss polyurethane

thinned with Mineral Spirits 60/40 and wiped on while lathe was turning.

He let dry between coats

John Sargent brought

in a guitar he made from a kit. It was Rosewood, Spruce, Ebony, and

Mahogany. A second guitar was shown that was made by Earl George

completely out of maple

John Sargent brought

in a guitar he made from a kit. It was Rosewood, Spruce, Ebony, and

Mahogany. A second guitar was shown that was made by Earl George

completely out of maple