SPLINTERS

Tennessee Valley Woodworkers

Vol. 17/ Issue3

March 2002

Editor: Tom Gillard Jr.

Vol. 17/ Issue3

March 2002

Editor: Tom Gillard Jr.

Meeting Notice:

The next meeting of the TN Valley Woodworkers

Will be held, March 19th at 7:00 p.m. in the

Duck River Electric Building, Dechard, TN

All interested woodworkers are invited!

The following people have agreed to serve as contacts for their particular

skills. If you have questions, suggestions

for activities, or other comments relating to these skills, please

call these folks. Their interest is to help the

club better serve their area of expertise. Your participation

with them will help them achieve that goal.

Alice Berry

454-3815 Design

Phil Bishop

967-4626 Finishing

Tom Church 967-4460

Turning

Harry May

962-0215 Carving

Bob Reese

728-7974 Sharpening

Ross Roepke

455-9140 Joinery

Maurice Ryan 962-1555

Health and Safety

List of

Club Officer

President: Bob Leonard

V. President: Doyle McConnell

Secretary: Barbara Keen

Treasurer: Henry Davis

Publicity: Maurice & Ruth Ryan

Newsletter Editor: Tom Gillard Jr.

GOD BLESS AMERICA!

CALENDAR of EVENTS

Spring seminar: April 20th @ Foothills Craft, Manchester

Picnic: June 22nd

Coffee County Fair : 3rd week in September

Fall seminar :October time frame

Christmas party: December 6

** It was also suggested that we should have another “turning B” and

possibly another carving workshop.

*dues are due*pay your dues*dues are due*pay

your dues*dues are due*pay your dues*dues are due* pay your dues*

WELCOME TO OUR NEW MEMBERS

We would like to welcome these new members who joined us in February:

Judy Babb

Jim and Lin Kemp

We are happy to have you with us.

SHOW AND TELL:

Jim Van Cleave brought in a Walnut table.

John Sargent brought a Maple vase and a segmented bowl made of Beech,

Cedar and Walnut.

Don Powers brought in two bowls one Walnut and and one Mahogany.

He used engraving tool for top embellishment.

Manuel Brown brought a bowl and a round cookie jar with lid.

He also brought in several different sizes of goblets he had turned.

Bob Leonard brought in a Shaker basket. He had ordered a kit

to make it from. He showed the jigs he made for bending it around.

He also brought the piece he made for bending over the copper brads.

He said it was fun to make it and he will be ordering patterns of the different

sizes so he can make more.

*dues are due*pay your dues*dues

are due*pay your dues*dues are due*pay your dues*dues are due* pay your

dues*

Notice from the Treasurer:

Just a reminder to those members who have not paid their dues for 2002.

In a few weeks we will have the very unpleasent task of clearing our membership

list of those folks that are no longer interested in being members of the

club. If you have not paid your dues hope to hear from you soon.

See Henry at the meeting or contact him at 393-3191 or hdavis@cafes.net.

$10 for singles

$15 for families

*dues are due*pay

your dues*dues are due*pay your dues*dues are due*pay your dues*dues are

due* pay your dues*

NAME TAGS

The subject of name tags came up at the last meeting. Our name tags

were made by K&S TROPHIES , 510 Country Club Drive , Tullahoma.

They were about $5.00 including tax the last time we checked. When in Tullahoma

you can go by and have one made. The tags are 1" x 3" with white letters

on a blue background. Just tell the folks that you want a Tennessee Valley

Woodworkers name tag. If you are never in Tullahoma, Henry Davis will be

happy to take care of it for you, see him at the February meeting or give

him a call at 393 - 3191.

*dues are due*pay your dues*dues are due*pay your

dues*dues are due*pay your dues*dues are due* pay your dues*

Mini Lathe Give Away.

To show our appreciation to our loyal and faithful members your Executive

Committee has again this year decided to give a prize to one lucky member.

To be eligible to win the lathe just sign the drawing register at each

regular club meeting that you attend between now and December. That means

that if you attended the January meeting and attend every meeting from

now through November your name will be in the drawing 11 times.

*dues are due*pay your dues*dues are due*pay

your dues*dues are due*pay your dues*dues are due* pay your dues*

*** THE TABLESAW

***

That tablesaws rank high as the cause of many woodworking accidents shouldn’t

be surprising. What woodworker doesn't have one? And it's probably the

most frequently used power tool in the shop. Because of that use, it'll

pay you healthy dividends to always be on guard around this

indispensable machine.

A multi-toothed blade whirling at 8,000 rpm,(238mph tip speed), should

spur a sense of caution and respect. It shouldn't instill fear. Armed with

the advice, rules, and techniques you'll find here, you'll have the confidence

to get the best out of your tablesaw, and safely, too.

Begin a habit-forming checklist to follow before sawing.

California Polytechnic Institute has developed a Code of Safe Practice

for a number of woodworking machines as a guide for operators and

supervisors in the industry. We've added to it, and suggest you always

follow the checklist before doing any cutting with your tablesaw in the

shop.

· Remove from the saw table all scrap materials,

tools, fasteners, and other debris. Also clear a 2' perimeter all around

the saw (more where you'll stand if ripping long stock).

· Use the blade that best suits the job (never

a crosscut blade for ripping or vice versa), and make sure it's sharp.

· Check the arbor nut for tightness and the

blade itself for chipped teeth, cracks, and other defects.

· Do all of this with the machine unplugged.

· Set the blade height. Flat-ground blades

should extend no more than 1/4" above the wood. Hollow-ground or planer

blades must be raised as high as possible to avoid binding. Inspect

all of your saw's safety devices (the blade guard, splitter, and anti-kickback

device, if present) for proper operation.

· The blade guard must move up and down freely

to accommodate different wood thicknesses.

· Double-check the location and condition

of the on/off switch. Realign the electrical cord to avoid tripping

over it. Set the fence to align parallel to the blade at the width

of the cut. Have safety glasses ready to wear, or if cutting material

that tends to chip, a full-face shield.

Because a tablesaw gets so much use in woodworking, turning it on to

make a cut becomes as automatic as flipping on a light switch. But it shouldn't.

Ponder this advice:

-

Never run your tablesaw when you're tired. Fatigue leads to errors in judgment

and mistakes. In fact, studies have shown that many serious tablesaw injuries

occur to woodworkers when most other people are getting ready for a good

night's sleep. Also, stay away from the saw if you're on medication or

have been drinking alcohol.

-

Don't rush. Plan all your cuts. When ripping stock, always anticipate

the possibility of kickback. Plan to minimize any damage from it to you

or the workpiece. For instance, don't stand directly in line with the blade,

but off to the side of it. To make sure your pushing hand won't accidentally

run into the blade, hook the small and ring fingers of the your pushing

hand over the fence to slide with the wood. If you're planning to

rip boards longer than 3', get a helper to support the wood after it passes

through the blade, or use an off-feed table or roller. All

cuts should incorporate either the fence or the miter gauge.

Never attempt freehand sawing. Turning the stock on the blade even slightly

causes it to bind in the wood and kick back. On the other hand, never use

the fence and miter gauge together. If you try to crosscut with the miter

gauge using the fence as a stop, for example, the cutoff piece trapped

by the blade may fly back at you.

-

Don't remove the blade guard from your saw unless absolutely necessary

to make a specific cut.

-

Make sure you have a pushstick handy

for any cuts that require your hand to pass within 6" of the blade.

If you have doubts about making a cut, don't do it.

TABLE SAW SAFETY

You've thought it through, now get in position to saw You've got everything

on hand, you've gone through the checklist and you've thought through all

your cuts. You're set to saw. And as you do, keep the following

in mind.

-

Stand with your weight equally balanced on both feet. If the board should

suddenly give, you don't want to run into the blade. Be absolutely sure

that the blade never comes between your body and your hands, either front

to back or side to side.

-

Use a feather board to hold stock against the fence. And make sure you

have a firm-pushing grip on it. As you saw, don't reach over the

blade to push stock. Always keep your hand as far away from the blade as

practical. If need be, use a pushstick. If you're making repetitive

cuts, stop frequently to take a break. Many accidents happen after boredom

lulls a person into carelessness.

-

After completing the cut, let the blade come to a complete stop on its

own. Don't push scrap wood against the blade to stop its rotation. When

you've finished sawing, turn off the tablesaw and lower its blade below

table height.

*dues are due*pay your dues*dues are due*pay your

dues*dues are due*pay your dues*dues are due* pay your dues*

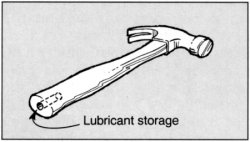

Tip of the Day

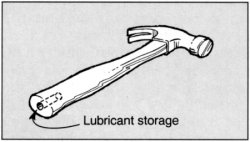

Handy lubricant storage

When driving a nail the wood

often splits. The same happens if

you drive screws without drilling pilot holes first.

TIP: Coat nails with beeswax or paraffin before nailing. Rubbing

lubricant into the threads of wood screws makes them easier to set. Also,

keep lubricant handy by storing it in a 3/8"-diameter X 3/4"-deep hole

drilled in the hammer handle. Melt beeswax or paraffin on a stove, then

pour it into the hole.

—From the WOOD® magazine shop

ATTENTION: Many thanks go out to all those who contributed

to the chair fund. Enough money was donated to purchase 15 new chairs.

The club now has 30 chairs of it’s own.

MONTHLY DRAWING: The drawing was done for two gifts since one was not done

last month. Loyd Murphy was a winner and chose the skill saw blade

and Larry shockley also won and chose the level.

Recall Notice for Roto Zip

Spiral Saws

The recall includes Revolution®, Rebel™ and Solaris™ model Spiral

SawTM power tools. The brand name and "ROTOZIP SPIRAL SAW" are written

on the side of the tools. The saws are mostly black or red. The recalled

saws include the serial numbers listed below:

|

Saw Model

|

Serial Number Range |

| Revolution® |

01 through 1,145,000 |

| Rebel™ |

01 through 415,000 |

| Solaris™ |

01 through 270,000 |

For more information, contact the Roto Zip Tool Corp. toll-free at (800)

920-1467 between 7 a.m. and 7 p.m. CT any day of the week, or

visit the firm's web site at www.rotozip.com

March Program:

Ray Hughes form Lenox Saw company and Doug Walston from Precision Saw

and Tool at 1055 Mt View rd, Morrison, TN will be presenting the program

for our club in March. The program will cover general blade selection

and use of the band saw.

WEB

SITES of INTEREST

Scott

Phillips Video Help sessions

Arrowmont

School of Arts and Craft

WOOD

ONLINE newsletter

Falls Mill

Appalachain

Center for the Arts

Forest

Products Lab. 1999 Wood Handbook

Find

A Tree - Hangman Style! Tree identification

game...

Woodworker's

Journal

WOOD

Online TVWW page

Kevin's Woodturnings

The Oldham Company

The Woodworker's Choice

Russell Brown's Web Page

Saw Blade Sharpening Services: Branching Out is now offering their

services as a drop off spot to have your saw blades sharpened. The

blades will be picked up (Tuesdays), sharpened, and dropped back off at

Branching Out. The Leitz Tooling Systems out of Collierville, TN

will do the sharpening. Call (393-0525) or stop by for details.

10 % OFF Fine Woodworking

Books from Taunton Press

…We’re open Monday thru Saturday

Webmaster:

Tom Gillard Jr.

Vol. 17/ Issue3

March 2002

Editor: Tom Gillard Jr.

Vol. 17/ Issue3

March 2002

Editor: Tom Gillard Jr.

![]()

![]()

![]()