SPLINTERS

SPLINTERS

Tennessee Valley Woodworkers

Vol. 16/ Issue12

December 2001

Editor: Tom Gillard Jr.

Vol. 16/ Issue12

December 2001

Editor: Tom Gillard Jr.

Meeting Notice:

The next meeting of the TN Valley Woodworkers

Will be held, December 18 at 7:00 p.m. in the

Duck River Electric Building, Decherd, TN

All interested woodworkers are invited!

The following people have agreed to serve as contacts for their particular

skills. If you have questions, suggestions

for activities, or other comments relating to these skills, please

call these folks. Their interest is to help the

club better serve their area of expertise. Your participation

with them will help them achieve that goal.

Alice Berry 454-3815 Design

Phil Bishop 967-4626 Finishing

Tom Church 967-4460 Turning

Harry May 962-0215

Carving

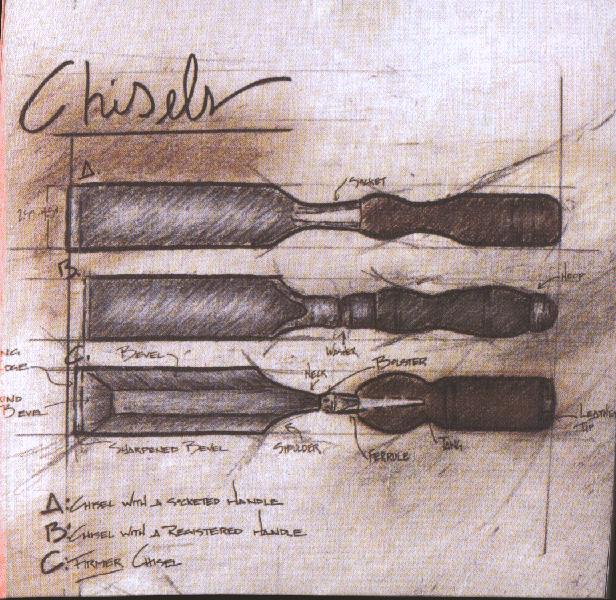

Bob Reese 728-7974 Sharpening

Ross Roepke 455-8310 Joinery

Maurice Ryan 962-1555 Health and Safety

The election results are in and here is the slate of new club officers

for 2002:

Bob Leonard -President

Doyle McConnell -Vice President

Barbara Keen- Secretary

Henry Davis -Treasurer

Ruth and Maurice Ryan -Publicity Chairmen

Congratulations to all and may we

have another fine year under new management.

The December meeting:

After much discussion with Doyle and Tom Cowan, we decided to have an extension

of Show and Tell and let each member bring samples of their early projects

and a recent project and demonstrate the difference. If members don't

have samples of early and recent, then feel free to bring what you have.

If you have a favorite tool or fixture, bring it. This will be the same

type program we had last December.

-----------------------------------------------------------------------------------------------------------------------------

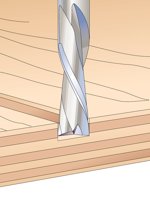

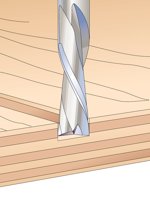

Spiral Bits

Downcut

As the name implies, the cutting action of this bit is downward, or

away from the router base. That shearing motion imparts a clean edge on

rabbets, dadoes, grooves, shallow mortises, and plunge cuts

in both sheet goods and solid stock. When cutting grooves or dadoes deeper

than the diameter of the bit, don't try to take the full depth at once.

Instead, make several progressively deeper passes. A downcut bit tends

to pack the wasted material down into a deep cut, rather than ejecting

it, and shallow cuts reduce the problem.

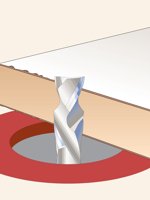

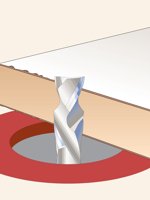

Upcut

This bit wasn't designed to leave a clean edge like a downcut bit,

but rather to remove the chips created in a deep plunge cut. That

makes it ideal for plowing out a deep mortise in solid stock. Tearout caused

by the upward shearing will be hidden by the tenoned workpiece.

You also can use an upcut bit in your router table for any edge

treatment that you perform with the workpiece face up, such as jointing

solid or highly figured stock. (Remember that in a router

table, the upcut bit is now cutting down.)

Upcut/downcut or compression bit

The unique geometry of this bit cuts from the top down and the bottom

up at the same time, and it's ideal for cleaning up the edges of hardwood

plywood or melamine-coated particleboard (MCP). For such easily chipped

materials, WOOD® magazine shop manager Chuck Hedlund first cuts the

pieces oversized on the tablesaw, leaving an extra 1/16" on all sides.

He then loads up a compression bit in the router table, setting the center

of the bit's cutting flutes to about the middle of the workpiece's

thickness. Finally, he offsets the outfeed fence 1/16" and joints

away the chipped edges.

-----------------------------------------------------------------------------------------------------------------------------

Tip of the Day

Know when to stop sanding

It's all too easy to sand through the thin veneer of plywood and fibercore

lumber when beltsanding a finished frame edge, whether in a cabinet

or a picture frame. Sanding frames that mount to the bottom of a few recent-model

belt sanders help,

but what if you don't own such an accessory?

TIP: Shade a wavy pencil line on the veneer edge that butts up against

the frame. Stop sanding the joint just after the pencil line disappears.

The same technique works well on banded tops and shelves.

—Terry Leach, Lovington, Ill.

Christmas Party

What a wonderful party!!! Such good food and fellowship.

Thanks to everyone that helped in the setup and clean up.

Congratulations to Maurice, the winner of the DeWalt router...

**I would like to thank the club for the wonderful gift that was presented

to me last night at the party. It was a complete surprise.

I am glad everyone enjoys the newsletter. I have hoped it would be

fun and informative, too. I will try to maintain the quality you

have come to expect.

Tom

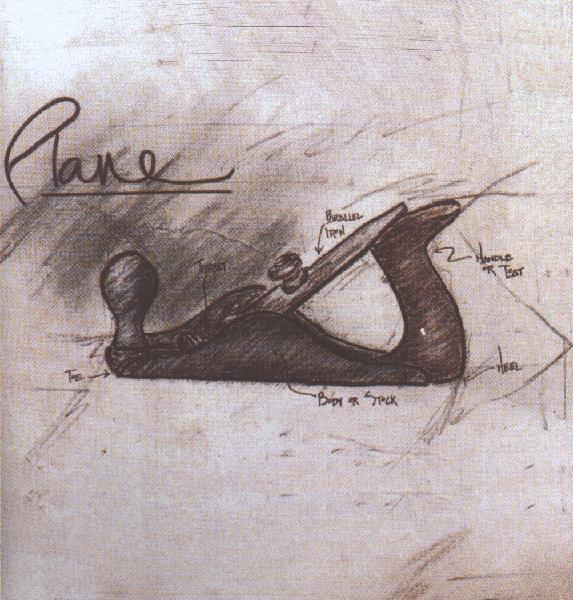

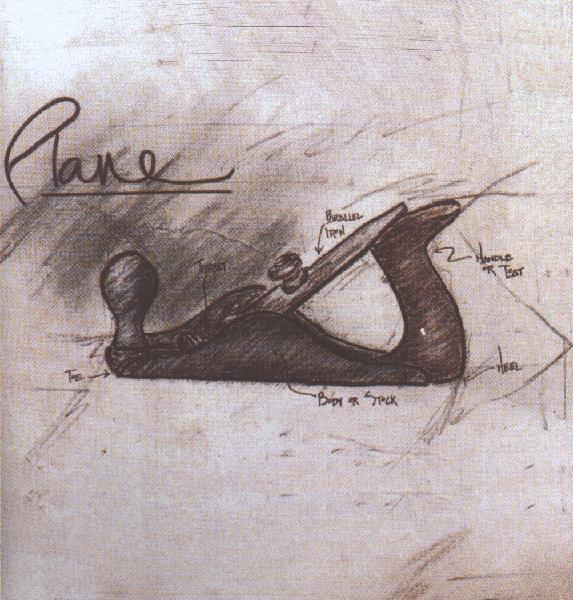

I certainly want to thank the members of Tennessee Valley Woodworkers

for

the nice gift I was presented at the Christmas party. It

was a Lee

Nielsen plane in a commemorative box. Things like this is suppose

to happen

to someone else. Thanks again for the gift and most of all for

the thought

and allowing me to be part of such a great organization.

Doyle

November Show and Tell

Bob Reese: #14 Violin out of Birdseye maple, 2 pecan bowls

and other bowls.

Steve Shores: Black locust bowl, sassafras bowl, and Bradford

pear bowl

David White: Two frames for decorative ceramic tiles.

Bob Lowrance: Finch, bird, that he carved while attending

the John Campbell Folk Art School

Ross Roepke: Magazine rack and “traveling cross” for a

minister.

Bob Leonard: Display stand for a Christmas ornament made

by Bobby Clemons

Doyle McConnell: A sample of the rosette blocks for his

daughter’s house and the jig he used to make them. Also, a sample

of the 80 spindles he is turning.

Hugh Hurst: Maple bowl. His first!

Manual Brown: Multi-wood species pencil boxes and three

maple and exotic woods segmented bowl having an American flag motif.

Jim VanCleave: Jewelry box with spline joinery and the

jig to cut the splines.

Jim Parker: Handkerchief table with hand carved Cabriole

legs.

Aaron Schroer: Marquetry plaque with Pokemon faces

John Troxler: Marquetry jewelry box from Italy

WEB

SITES of INTEREST

WOOD

ONLINE newsletter

Arrowmont School

Falls Mill

Appalachain

Center for the Arts

Forest

Products Lab. 1999 Wood Handbook

Highland Hardware

Woodworker's

Journal

WOOD

Online TVWW page

Kevin's Woodturnings

Precision Blade and Tool

Saw Blade Sharpening Services: Branching Out is now offering their

services as a drop off spot to have your saw blades sharpened. The

blades will be picked up (Tuesdays), sharpened, and dropped back off at

Branching Out. The Leitz Tooling Systems out of Collierville, TN

will do the sharpening. Call (393-0525) or stop by for details.

Webmaster:

Tom Gillard Jr.

SPLINTERS

SPLINTERS

Vol. 16/ Issue12

December 2001

Editor: Tom Gillard Jr.

Vol. 16/ Issue12

December 2001

Editor: Tom Gillard Jr.

![]()

![]()

![]()

![]()