SPLINTERS |

|

Tennessee Valley Woodworkers Vol. 15/ Issue 11 November 2000 Editor: Tom Gillard |

||

|

|

Meeting Notice: The next meeting of the TN Valley Woodworkers Will be held, November 21, 2000 at 7:00 p.m. in the Duck River Electric Building, Decherd, TN All interested woodworkers are invited! |

|

The following people have agreed to serve as contacts for their particular skills. If you have questions, suggestions for activities, or other comments relating to these skills, please call these folks. Their interest is to help the club better serve their area of expertise. Your participation with them will help them achieve that goal.

Alice Berry 454-3815 Design Phil Bishop 967-4626 Finishing

Tom Church 967-4460 Turning Harry May 962-0215 Carving

Bob Reese 728-7974 Sharpening Jim VanCleave 455-8150 Joinery

Maurice Ryan 962-1555 Health and Safety

Christmas party will be Dec. 8th, 6:00 PM at the Decherd Nazarene Church (Richard's Church). There will be door prizes, musical entertainment, and a potluck dinner. I hope this date works for most and hope everyone can attend. More about the party at our next meeting.

Thanks,

Tom Cowan

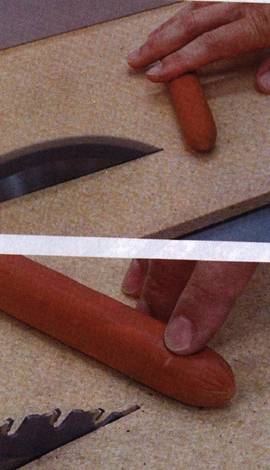

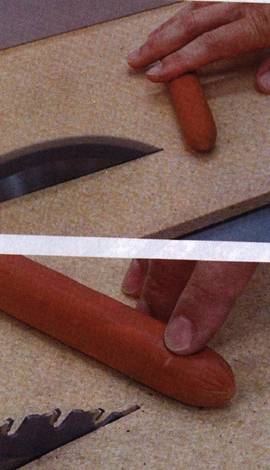

It’s about time someone invented a tablesaw safety rig that doesn’t get in the way and actually stops the blade before it can do any serious damages. The SawStop, invented by Steve Gass, a woodworker and physicist, uses an electromechanical device that stops a sawblade should fingers-or hot dogs- accidentally touch the spinning blade.

The SawStop electronically senses when flesh makes contact with the blade and immediately sends a signal to a box, which jams a plastic rod into a gullet of the blade, then retracts the bade, too. All of this happens in milliseconds. As demonstrated in Atlanta using hot dogs, typical tablesaw accident will result in a shallow cut (about 1/32”) instead of an amputation. Wood plastics or wood products do not affect the device. All of SawStop’s components are neatly tucked away under the saw.

Unfortunately, SawStop is not available as a retrofit. Rather, the company is offering the technology to tool manufactures that would have to redesign current tablesaws. Gass says the device would add only $50 to $100 to the cost of a new saw. He has been busy talking to most of the major tool companies.

SawStop was awarded one of seven Challengers Distinguished Achievement Awards at the IWF show. It’s the most innovative safety device we’ve seen in a long time.

Fine Woodworking Dec. 2000 #145

Follow the path of the unsafe, independent thinker. Expose your ideas to the dangers of controversy. Speak your mind and fear less the label of 'crackpot' than the stigma of conformity. And on issues that seem important to you, stand up and be counted at any cost.

Thomas J. Watson

November program will demonstrate the use of coran instead of wood.

TENNESSEE VALLEY WOODWORKERS MINUTES OCTOBER 17, 2000

President Tom Cowan called the meeting to order at 7:00 P.M.

Welcomed guests were Ken Delaney and new members were Howard Vaughan and Wayne Hawkersmith.

ANNOUNCEMENTS:

Doyle McConnell remarked that he was proud of club members that turned out for the Coffee County fair and thanked all members that participated. Tom Cowan expressed thanks to Juel McConnell for teaching club members to bottom stools. Completion of several stools was achieved.

Bob Leonard announced that Alan Noel would present a seminar on wood finishing on October 28, 2000. The event will be held at Tom Gillard’s shop in Tullahoma, TN and the cost will $25.00. The event will be from 8:30 A. M. to 3:30 P. M.

Tom Cowan announced that Bennies woodworks in Shelbyville, TN are having an inventory reduction sale on October 27th and 28th, 2000.

Loyd Ackerman announced that the nominating committee for officers for the next year is not ready to present names for consideration at present. The secretary position has not been filled. Loyd asked for volunteers. The election is to be held in December.

Henry Davis announced that nametags could be purchased for $5.00 each. Also, Henry announced that copies of “splinters” are available at the meeting.

Bob Leonard announced that copies of an article about moisture meters are available at the meeting. Also, bob told of a recent trip to Berea and Shakertown, KY and indicated that it was an interesting place to visit to see woodworking projects.

Tom Cowan announced that the November program would demonstrate the use of coran instead of wood. The December program will be an extension of show and tell and each member is asked to bring a project made early as a woodworker and a recent project and demonstrate the difference. Also, bringing a favorite tool to the meeting would be an interesting item to discuss.

Doyle McConnell showed a recently purchased arm holder for a bowl scraper used to hollow vases.

Jack Bagggenstross-displayed a small steam engine and several old wood working chisels.

John Mayberry-maple bowl.

Ross Roepke-experimental hinge and a catalogue of “tools” buyers guide that comes out once a year.

Manual Brown-two bowls with multiple varieties of wood. One bowl had a plate for a bottom.

Bob Reese-replacement blades for violin maker’s planes. In addition, several other small plane blades and small plains. Also, a jig for holding small plane blades for sharpening.

Tom Cowan-large pitcher that won first place at Arrowmont, woodworkers convention in Gatlinburg, TN and a blue ribbon at the Coffee County fair.

Loyd Ackerman-small tops, bottle stoppers and key chain ornaments.

Tom Gillard-two 71/4 inch saw blades and a 10-inch plywood blade to be given as prizes at the October seminar at his shop.

PROGRAM

Ross Roepke presented an interesting program on the use of radial arm saws. Ross showed several jigs to be used with the radial arm saw. Maurice Ryan handed our literature on tablesaws.

There were a total of 45 members and guest in attendance.

Respectfully submitted, John Mayberry, secretary.

Never fear the want of business. A man who qualifies himself well for his calling, never fails of employment.

Thomas Jefferson

The tree that has stood the test of time

In early geologic time there were many species in the Osage orange family. Today, however, it stands alone as the only tree in the world that is the sole species in a genus.

Fossils indicate that Osage orange (Maclura pomifera) once grew naturally well outside its native range of Texas, Oklahoma, Louisiana, Missouri, and Arkansas. Then it retreated, perhaps ahead of advancing glaciers. Thousands of years later, because it was cultivated and planted by settlers as inexpensive fencing, it once again spread. Now, you may even find Osage orange growing in the eastern states and well into the Great Plains.

Wherever Osage orange grew, it had many a use. At one time, a Plains Indian brave would gladly trade a horse and blanket for a bow made of the wood. The reputation of such bows spread widely from the land of their makers-the Osage Indians of Arkansas and Missouri. Bows of this hard, strong wood were even found by explores in use as far north as Montana. That’s why in many parts of the nation the wood carries the name bois d’arc, French for wood of the bow. Americanized, the term became bowdark.

Harder and stronger than even white oak, Osage orange was once cut for railroad ties. While other woods for ties lasted but a few years, Osage orange served for 20! And many a midwestern farm still has fence posts of the wood in place after a century. Because of Osage orange’s hardness and durability, it often was used for wagon wheels. Highly decay-resistant, it was even laid as paving blocks. In today’s world, however, the wood is scarce as lumber. Yet sanded smooth and oiled, Osage orange beats all others for cutting boards that will stand up to a blade.

WOOD (DEC 2000 #129)

….cautions against the use of auto wax because it contains silicone that can get onto wood and cause finishing problems. Indeed, I have experienced fisheyes in my finish caused by using auto wax. It is a difficult problem to overcome. I use a beeswax and turpentine paste on my machine tops.

We heard from several readers on this one. Anything with silicone in it should be kept off surfaces that come in contact with your wood. ….uses a mixture of equal parts kerosene, paraffin, and machine oil. We use a paste floor wax on the cast-iron tool tops in the WOOD shop.

Bent

on success

Bent

on success

Well-used hinges have a tendency to loosen with age. If the problem goes unchecked, some doors won't close properly.

TIP: A bent hinge pin makes a lot of difference in how an old hinge operates. Tap the pin slightly in the center to create a bend. The hinge should open and close with a smoother action.

—From the WOOD® magazine shop.

Club officer nominations are this month. We promise that the elections next month will be quick with no mis-punched ballots and no recounts.