SPLINTERS

Tennessee Valley Woodworkers

Vol. 12/ Issue 9 September,

1998 Editor:

Tom Gillard

Meeting Notice:

The next meeting of the TN

Valley Woodworkers

will be held, September 15th

at 7:00PM at the

Duck River Electric Building

in Decherd, TN.

All interested woodworkers

are invited!

On

the Road Again...

Four

members of the TVWW club (Doyle McConnell, Henry Davis, Tom Cowan, and Loyd

Ackerman)

attended

the Tennessee Association of Woodturers Annual Symposium at the Arrowmont Craft

school on

August

21, 22, and 23. The symposium included five Presenters: Rude Osolnic presented

his famous candle sticks; Willard Baxter presented both natural edge bowls and

ornaments; Larry Haisaic showed how to do hollow vessels and ornaments; Al

Stirt turned, carved, and painted bowls; and Bob Vaughn did a show on how to

tune up bandsaws and lathes. The symposium started Friday night with a

roundtable. Saturday and Sunday were filled with presentations, eating, and

sitting on the screen porch listening to conversations ranging from the

downright interesting to well- er, you know.

It was a lot of fun.

WOOD

FACTS

American

woodworker (Feb 1994)

Mahogany

SPECIES

Primary

Species: Swietenia macrophylla mahogany-Central and South America)

(Bigleaf

TRADE

NAMES

Some

woods traded under the name, “mahogany,” only those belonging to the genus

Swietenia are true mahoganies (sometimes sold as “genuine.” “New World”- or

“American” mahogany). Of true mahoganies, only big leaf mahogany (S.

macrophylla) is still widely available commercially. It is often denominated by

its country of origin (Brazilian mahogany, Peruvian, etc.). The common trade

name, “Honduras mahogany,” is inaccurate – over harvesting has greatly depleted

that country’s supply. The finest mahogany, Santo Dominican (S. mahogany, also

called “Cuban” or “Spanish” mahogany), has also been over harvested and is no

longer generally available except a windfalls after hurricanes. though similar

in color, “African mahogany” (Khaya spp.)

and

“Philippine mahogany” or “lauan” (Shorea spp.) are not true mahoganies.

APPEARANCE

Mahogany

is usually bright reddish pink when freshly cut, but it turns to a coppery

reddish brown with

exposure

to light. Denser wood tends to be darker. The sapwood is cream-colored and

thin. The large, plentiful pores are often plugged with white or yellow

deposits of gun, calcium or sulfur. The grain is primarily straight and plain,

though rarer logs of rippled, curly, fiddleback, blistered, striped, mottled or

quilted wood occasionally appear. Flats awn planks sometimes display darkly

swirled growth rings, while quartered planks are nearly devoid of grain lines.

WORKABILITY

Mahogany

is prized for its stability and workability and is ideal for most woodworking

applications. It glues well and is easy to work with both machine and hand

tools, although its interlocked grain is susceptible to tear-out. Its

resiliency helps it resist dents.

TECHNICAL

PROPERTIES

With

a specific gravity range of 0.54 to

0.64 (34 to 40 lbs/cubic ft.), mahogany is a light- to medium-density hardwood.

It dries well, moves very little in service and is durable enough for most

outdoor uses. Although the thin sapwood is vulnerable to boring insect attack,

the heartwood is fairly resistant. Quartersawn stock is preferred by pattern

makers because of its high stability. Mahogany requires pore filler for a

smooth finishjhough unfilled oil finishes produce an attractive leathery

‘pigskin’ color and texture. Mahogany takes dark stains beautifully and can be

finished to a high luster.

USES

Mahogany

is used for fine furniture, paneling, boats, caskets, musical instmments,

pattern making, carving and signs. Highly figured logs are especially prized

for sliced veneer.

SIZES

mahogany

trees can grow more than 100 ft. tall and up to 12 ft. in dia. Typical boards

are 6 in. and wider and 8 ft. and longer, and are available in all standard thicknesses

from 4/4 through 16/4.

SUSTAINABIL1TY

Mahogany

is not currently banned from import or export, though it has been recognized as

potentially endangered by the ‘CiTES’ (Convention on International Trade in

Endangered Species) Treaty of 1992. Certification, restrictions and boycotts

are currently under discussion.

AVAILABILITY

Mahogany

is readily available in several grades, mostly “FAS” and” select and better”

though larger lumber dealers and wholesale mahogany specialty companies.

COST

Though

prices for mahogany vary greatly, the wholesale price range (100 bd. ft. and

up) of 4/4 FAS grade is $2.25 to $3.00 per bd.ft., with premiums for longer,

thicker and wider stock. Quartersawn wood and figured wood are also priced

substantially higher.

A

MINUTE with John Green:

VWW August 1~, 1998

Meeting

called to order by President Harold Hewgley. Guests welcomed were John and

Melissa Hinson. Also, Kathryn and Benjamin Mills, the and infant son of Will

Mills. New member Gary was introduced.

Welcome Gary.

Old

business - Falls Mill is scheduled for September 12, 1998. Hours are 9:00 AM to

4:00 PM with set-up after 7:00 AM. Janie Lovett reported that Sean Metric will

be making chairs.

Carving

seminar-Date changed to October 17, 1998, because of a schedule conflict.

Schedule and sign up sheet will be available next month.

Picnic

- September 12, 1998 at Duck River Richard Gulley and Tom Church co-chairs.

New

business - Tennessee Wood Turners symposium will be held August 21-22 -23,

1998, at Arrowmont. Loyd Ackerman, Tom Cowan, Henry Davis and Doyle McConnell

will be attending.

Randy

Walker a wood carver from Columbia will be the program presenter at fife

September meeting. A program on sanding will be either October or November.

Show

and Tell -

J. Van

Cleave - a clock made by Jack Townsend,

H.

Davis - two turned bowls. All Atlas

cedar and a footed bowl.

T.

Gillard - Two portable bowsaws used in Scouting, a polyurethane glue

demonstration and spruce models used for testing in wind tunnels.

After

a short recess Loyd Ackerman introduced Jim Van Cleave who presented a program

on old tools. Jim was aided and abetted by Richard Gulley, Phil Bishop, and

Henry Davis. Meeting adjourned at 8:48 PM.

Respectfully

submitted, John Green.

NEW

MEMBERS

Welcome

new members, Ken Burgess, who joined in

July

and Tommy Thomas, who joined in Aug.

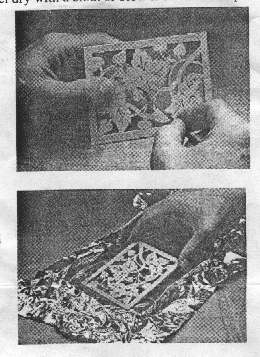

FINISHING

FRETWORK

Here

are a couple of tricks you can use to put the finishing touches on fretwork

panels.

Tiny

ridges, kerfs, and bums marks are common problems. Traditionally, small files

(rifflers) are used for getting into the fretwork openings. But we found that a

inexpensive modern diamond file works just as well, in some instances better,

see photo below left.

As

for applying a finish, we get into the tiny openings by dipping the panel in an

oil finish, see photo below

right.

To remove the excess finish, you can blot the panel dry with a cloth or blow it

out with compressed air.

For

final touch-ups. use a half-round diamond file. It has a round side and a flat

side for both curved and flat edges.

When

dipping a fretwork panel, aluminum foil shaped into a tray acts as a reservoir

for the oil finish.

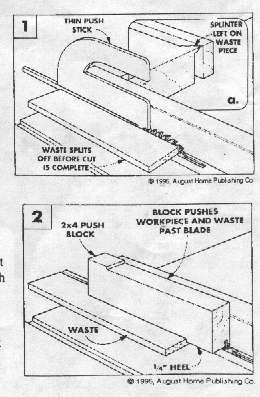

PUSH

BLOCK for CUTTNG THIN STRIPS

Typically

when ripping thin stock, I use a thin push stick, see Pig. 1. But I’ve noticed

a problem with this technique. As the

push stick moves the work piece past the blade, the waste side of The work

piece can split off just before the cut is completed. This leaves a little

triangular splinter of wood on the waste piece, see Fig. 1a.

If

you’re making a Series of thin strips, that splinter can keep the work piece

from going tight against the fence on the next pass. (Or sitting flat on a

jointer table, if you’re jointing between passes.)

Though

the splinter can be trimmed off with a pocketknife or chisel, here’s a solution

that prevents the splinter in the first place.

Use

a push black made from an 11” long piece of 2x4, see Fig.2. Cut out or glue on

a 1/4” “heel” on the bottom of the block. This pushes both the work piece and

the waste through the blade, eliminating the little splinter.

By

adding a heel on top of the block, too, you can just turn the block over when

the first heel gets too torn up.